704-841-2001

Backed with a massive machinery database considered to be “the blue book” of woodworking machinery), EX-FACTORY Auctions provides a complete assessment of your equipment and allows you to interact with the market real-time in our dynamic Online Auction!

Industry

Woodworking

1853 Results Found

704-841-2001

$15,290

SCMI Sandya 3S/ RCS 37" double head wide belt sander37" width cap. Drum, Combination Head1st head: 4.5" diameter steel contact drum with manual grit set2nd head: 4.5" rubber drum with 2" wide soft platenSpecifications -- 30HP 230v 3ph drive -- Delta soft start motor controls -- Electrical requirements: 91amps -- Anti-dubbing control of platen rise-fall to protect leading and trailing edges of panels -- Variable speed conveyor by inverter 12-60 fpm with digital display for working height -- Automatic thickness set up -- 6.6" max thickness capacityEquipped with & Features -- Automatic conveyor belt tracking (pneumatic cylinder) -- Two platens, soft (for veneer), semi-stiff (solid wood) -- 50 durometer conveyor belt -- 2 roller infeed and outfeed roller tables -- 4 Top and bottom fastened jack screws -- Manual adjustment of contact roller and platen positions1800 CFMTwo (2) 5" dust ports

$7,950

SCM - K 203 F: Edgebander0.4 to 5 mm Max. edge cap. for strip feeding; 1/8" (3 mm) for coil feeding; 60 mm min. panel width; 160 mm min. panel length; panel thickness: 10 - 50 mm. Equipped with: -- Teflon coated glue pot (heat-up time 10 - 15 min.); automatic strip &coil feed magazine; 3 mm cap. guillotine; 3-roll pressure unit w/pneumatic control.Workstations -- Double motor front & rear-end trim mounted on: THK Guideways (0.4 HP - 12,000 RPM motor ea.); tilts 0° - 15° from the control panel with: (2) Preset positions. -- Top & Bottom flush & bevel trims with: Quick release mount & plug-in motors for quick tooling changes; 0.7 HP - 12.000 RPM motor ea.; bevels 0° - 15° with: Precision digital indicators for quick setup. -- Top & Bottom scraping unit with: Pneumatic positioning from the control panel; Top & Bottom buffing unit, 0.25 HP - 2,800 RPM motors. -- 36 FPM Fixed feed speed; 0.75 HP feed drive.Includes Microprocessor for line control (store up to 50 preset programs); control panel at eye level for ease of programming; full cover sound enclosure.Features. Mechanical digital readouts for setup adjustments; frequency inverter; outboard panel support.

$35,000

SCMI - OLIMPIC K230R EVO: Edgebander (w/Premilling) -- Specifications0.4mm to 3mm Edge thickness; panel thickness 8 mm to 50 mm (0.3" to 1.96"); minimum part width 60mm (2.36"); minimum part length 160mm (6.30").Minimum distance between panels: 559 mm (22";); 29-1/2 FPM (98 MPM) fixed feed speed; 1.0 HP (0.75 kW) feed drive.Premilling Station(2) 2.0 HP (1.5 kW) Motors to rectify/clean panels already sized. -- Adjustable infeed fence: Manually preset with digital indicator, pneumatic in/out positioning.Equipped with: 1.5 kG Teflon coated glue pot; glue roller application system complete with: Automatic recycling device for unused glue.Digital thermostat adjustment for temperature control; pneumatic guillotine; heating time approx. (8 - 10) Min.3-Roll pressure unit with: Pneumatic controls for all pressure rollers. -- Automatic strip & coil feed magazine.Workstations2-Motor front & rear End Trimming (1/2 HP - 12,000 RPM ea. motor.); tilts 0° - 15°; end trimmers mounted on THK guide. -- Top & bottom flush & bevel trims with: Quick release mount and plug-in motors for quick tooling changes.0.5 HP - 12.000 RPM Motor ea.; bevels 0° - 15° with: Precision digital indicators for quick setup. -- Top & bottom scraping unit with: Manual positioning. -- Top & bottom buffing unit (1/4 HP - 3,000 RPM motors); tilts up to 12°. Operator & Machine Control"ORION 1 Plus" Controller: Located at the infeed of the machine; capable of operating all the work units via soft touch buttons.It pneumatically tilts the end trim unit from the control panel; eliminates the use of micro switches, as well as control the temperature of the glue.Control is tilted slightly upward for a more ergonomically friendly position for the Operator. -- Actual Model is: SCM OLIMPIC K230R EVO.

Call for Price

SCM - OLIMPIC K 360ERT HP: Compact Edgebander (w/Premill)Specifications -- Edge Capacity: 0.4 - 6 mm (0.016 to 1/4") For strip feeding. -- Panel Capacity: Min. width: 65 mm' 140 mm min. length: 2-3/8" & 5-1/2"). Panel thickness min./max.: 8 - 60 mm (3/8" - 2-1/2").Equipped with: -- Adjustable infeed Fence: Manually preset with digital indicator; pneumatic in/out positioning. -- Premilling Station, RT-VP: Spindles: 2 x 2.0 HP - 19,000 RPM: (1) With PLC controlled jump action & diamond cutterheads. -- Automatic Strip & Coil Feed Magazine: For straight edges and 3 mm guillotine for coils. -- Gluing Station: For EVA (Hot Melt) with Teflon coated glue tank & quick disconnect to change glue tanks fast if needed; heat up time: Approx. (10) Min. -- Pressure Section: Manual digital positioning; (3) pressure rollers, first larger: Teflon coated & powered. Workstations -- End Trimming Station: Front & rear 2 x 1/4 HP - 12,000 RPM motors; mounted on THK guides; swivels 0° - 15°; rapid setup between straight & angled cutting with: Automatic swivel cylinder. -- Trimming Unit Flush/Bevel/Radius: Top/Bottom remote (via control panel) pneumatic positioning for (3) settings: Flush/bevel/radius trimming; (2) x 0.7 HP - 12.000 RPM motors with: Precision digital indicators for quick setup. -- Profile Scraping Unit "RAS/V": Top/Bottom; manual preset up with: Digital indicators; large dia. copy wheels for max. accuracy & pneumatic in/out positioning. -- Buffing Unit: Top/bottom; (2) x 1/4 HP - 2,800 RPM motors; tilting up to 12°. Controls -- ORION "1 Plus" Controller: Fixed at infeed of machine with: "Touch Screen" Control with soft keys; graphics; LCD display panel; handles most machine setup functions & workstations. Complete with & Features: -- Feed speed: 36 FPM Fixed; (1) x 2.0 HP feed drive motor; 200 Hz frequency inverter for all trimming units. -- Manual adjustable holddown pressure beam; full sound enclosure cover & outboard panel support. -- Actual Model is: SCM OLIMPIC K 360R HP

$67,000

SCM OLIMPIC K360 ERT HP: Compact Edgebander (w/Premill & Corner Rounding)Specifications -- Edge Capacity: 0.4 - 6 mm (0.016 to 1/4") For strip feeding. -- Panel Capacity: Min. width 65 mm & 140 mm min. length (2-3/8" & 5-1/2"); panel thickness: Min./max. 8 - 60 mm (3/8" - 2-1/2").Equipped with: -- Adjustable Infeed Fence: Manually preset with digital indicator, pneumatic in/out positioning. -- Premilling Station RT-VP: Spindles (2) x 2.0 HP - 19,000 RPM; (1) with PLC controlled jump action & diamond cutterheads. -- Automatic Strip & Coil Feed Magazine: For straight edges & 3 mm guillotine for coils. -- Gluing Station for EVA (Hot Melt) with: Teflon coated glue tank & quick disconnect to change glue tanks fast if needed; heat up time: Approx. (10) Min. -- Pressure Section: Manual digital positioning; (3) pressure rollers: First larger; Teflon coated & powered. Workstations -- End Trimming Station. Front & rear: (2) x 1/4 HP - 12,000 RPM motors; mounted on THK guides; swivels 0° - 15°; rapid setup between straight & angled cutting with: Automatic swivel cylinder. -- Trimming Unit Flush/Bevel/Radius: Top/Bottom remote (via control panel) pneumatic positioning for (3) settings; Flush/bevel/radius trimming; (2) x 0.7 HP - 12.000 RPM motors with: Precision digital indicators for quick setup. -- Corner Rounding Unit "Round 2M" with: (2) 0.8 HP Independent motors that slide on THK guides. -- Profile Scraping Unit "RAS/V": Top/Bottom, manual preset up with digital indicators; large dia. copy wheels for max. accuracy & pneumatic in/out positioning. -- Buffing Unit: Top/bottom; (2) x 1/4 HP - 2,800 RPM motors; tilting up to 12°. Operator Interface -- ORION "1 Plus" Controller. Fixed at infeed of machine with: "Touch Screen" control with soft keys, graphics, & LCD display panel; handles most machine setup functions & workstations. Complete with & Features -- Feed speed: 36 FPM Fixed; (1) x 2.0 HP feed drive motor; 200 Hz frequency inverter for all trimming units. -- Manual adjustable hold-down pressure beam; full sound enclosure cover; outboard panel support. -- Actual Model: SCM OLIMPIC K360 ERT HP

Call for Price

//This machine is in an Auction on exfactoryauctions.com// //Link to machine: http://exf.ac/i6d SECO SK-20BS 20" Vertical Band Saw Specifications: Actual throat 18-1/4". Table size 22-3/4” LR x 20-1/4" FB, with 45° Tilt. Max. height under guard 12". Blade length 155", Blade width 1". Wheel speed 800 RPM. Equipped with: 3 HP - 3,450 RPM Motor. 20” Rubber-covered cast aluminum wheels. Complete with: Work light.

Call for Price

SEDA T-REC XXLTechnical Data --Tire dimensions 13″ – 22″ Steel/Aluminium --Max. working pressure 2364 psi --Voltage 230 V / 3 x Ph + N / 5,5 kW / 60 Hz --Dimensions 90.5 x 51.2 x 59″ --Weight 2756 lbsBenefits --Suitable for all tire types (including Run Flat) --Rim sizes up to 22 inches (aluminum and steel) --Quick disassembly --Guaranteed destruction of tires and rims --Laser-assisted alignment

Call for Price

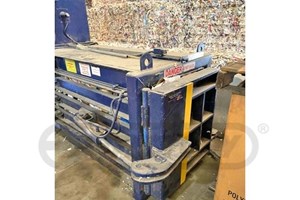

SELCO - HL-12-LH: Horizontal Baler with Infeed Conveyor• Motor: 20 HP. • Main Cylinder: 6";.• Hopper Opening: 50"; x 28";.• Cycle Time (No Load): 15 Seconds.• System Pressure: 2,000 PSI.• Total Compression Force: 56,556 Lbs.

Call for Price

SELCO - HLO-608-A40: Wide Mouth Auto-Tie Horizontal BalerSpecifications: -- Bale size: 48"; x 40"; x 72";. -- Main motor: 50 HP. -- Cylinder: 8". -- Twister motor: 2 HP. -- Cooler motor: 2 HP. -- (4) Tension cylinders: 5" Bore.Available NOW!

Call for Price

SELCO HSO-128A50: Horizontal Auto-Tie Baler -- Type: Open end. -- Cylinder: 8". -- Motor: 50 HP. -- Infeed opening: 36" x 28-1/2". -- Bale size: 30" x 40" x Variable. -- Bale weight: Up to 1,200 Lbs (OCC). -- Production capacity: 2 to 4-1/2 TPH. -- Shear blade. -- Hopper size: 36" x 28-1/2". -- Ram face pressure: 103 PSI. -- System pressure: 2,400 PSI. -- Platen force: 120,637 Lbs. -- Cycle time: 11-1/2 Sec (no load).

$93,580

SELCO WNT 7/730 REAR LOAD, AUTOMATIC PANEL SAW -- Specifications: 177" (4,500 mm) Overall cutting length, 5" (127 mm) max. saw blade projection, 29 HP (22 KW) main & 3.5 HP (2.6 KW) scoring motor. -- Saw Carriage:Variable saw carriage speed from 0 - 606 FPM (0 - 185 MPM), return speed 600 FPM (185 MPM); Rack & pinion drive, driven by AC brushless Servo motors. -- Pusher Fence:Electronically controlled overhead program fence with (8) pneumatic gripper clamps (open up to 5" / 128 mm).Forward speed of 295 FPM (90 MPM) & return speed of 295 FPM (90 MPM); rack & pinion drive, driven by AC brushless Servo motors. -- Operator & Machine Control:PC front end with Selco "OSI" + WINDOWS "7" operating system with easy programming of very complex cutting patterns.15" Flat screen monitor displays REAL-TIME graphics of cutting dimensions & patterns, program cutting list, manual cuts, diagnostic & on-line help.Data input by industrial keyboard & mouse, floppy disk or CD; direct downloading from office PC is possible.OSI (Open Selco Interface) guarantees fully automatic management of cutting patterns by optimizing all machine movements (pressure beam, saw carriage and side aligner pusher positioning, etc.).The numerical control adjusts the optimum saw blade projection for the stack of panels being cut and sets the most appropriate cutting speed, in relation to the stack itself and, when necessary, to the width of trim cut too. -- Rear Load Lift Table:Automatic lift table 173" x 87" (4,400 x 2,200 mm), 12,000 Lbs (5,455 KG) lift capacity.4 HP (2.3 kW) Motor for raise-and-lower, encoder-controlled guide rods for automatic book height adjustment; 28.7" (730 mm) max book height w/o a pit or risers. -- Rear of machine:(3) Lateral aligners to accurately position book of panels on rear table prior to cutting.Rear modular roller support rails with 80 mm dia rollers; rear of machine enclosed for safety. -- Front of machine:Automatic side/crosscut aligning device located inside the pressure beam aligns the panels against the right angle fence prior to cross-cutting, 2.4" - 87" (60 - 2,200 mm) stroke.90" (2,300 mm) Long crosscut fence (front-to-back); (4) Front mounted air flotation tables with rounded fronts 26" x 81" (650 x 2,050 mm). -- Complete with: "Quick Change" saw blade system; "DIGISET" electronic scoring adjustment; Selco "Quick-Opti" optimizing software; CP link. -- Options Include:173" x 87" (4,400 x 2,200 mm), LH facing, rear in-feed/out-feed conveyors with fork cut-outs that allow for staging/loading/unloading from the Rear LH side of the machine. Thin material loading capability. -- Actual Model is SELCO WNT 7/730/4500.

$17,010

SELCO EB 70 L CNC Front-Load Horizontal Beam CNC Panel SawSpecifications & features: -- 126" (3,200 mm) Overall cutting length, 2.75" cutting height (80 mm saw blade projection), 10 HP main & 3 HP scoring motor. -- Modular roller rear machine table, side aligning device for squaring ripped strips out to 59". -- Variable saw carriage travel speed from 0 - 164 FPM (0 - 50 MPM). -- Electronically controlled overhead program fence, rack & pinion driven, forward speed of 80 FPM, 131 FPM return speed.Equipped with: -- (6) Clamps (open up to 70 mm - 2-3/4"), (3) are closely spaced in crosscut area & (4) are at equal distance in rip cut area; AC Servo motor drives on both saw carriage & pusher fence. -- PC Controller with: Graphics color monitor & "Assist Line"; LED readout integrated into "high tech" look operator control panel (displays cutting dimensions & patterns), (400) cutting patterns with (50) different dimensions for ea. pattern, self-diagnostic. Machine features: -- 1,500 mm (59") Long crosscut fence (front-to-back), (1) side/crosscut aligner. -- (1) Front mounted air flotation table in the crosscut area and (2) front mounted air flotation tables with patented rounded front for moving panel from rip to crosscut position (24" x 59" each). -- 36" Working height; rear of machine partially enclosed for safety.

$11,900

SELCO - EB 90 4300: CNC Front Load Panel SawSpecifications -- 173" Overall cutting length; 173" pull back; 3.3" (85 mm) max. saw blade projection; 12 HP (9 kW) main saw motor; 2.4 HP (1.8 kW) scoring motor. -- Modular roller rear machine table; side aligning device; (2) longitudinal aligners to accurately position book of panels on rear saw table prior to cutting. Equipped with: -- Variable saw carriage travel speed from 0 - 197 FPM (0 - 60 MPM); return speed: 197 FPM (60 MPM). -- Electronically controlled overhead program fence; rack & pinion driven; forward speed: 0 - 197 FPM (0 - 60 MPM); return speed:197 FPM (60 MPM). -- (9) Clamps (open up to 85 mm); AC Servo motor drives on both saw carriage & pusher fence.CNi "NC 400 Plus" control with: Color monitor & "Assist Line" with: LED readout (displays cutting dimensions & patterns; virtually unlimited storage capacity of cutting patterns & different dimensions."Assist Line" with: Real-time graphics; self-diagnostic; data input by keyboard or possible direct downloading from an office PC. Complete with: -- 90" (2,300 mm) Long crosscut fence (front-to-back); (2) side/crosscut aligners; "Quick Change" saw blade replacement system. -- (4) Front mounted air float tables with: Rounded front 24" x 79" for moving panel from rip to crosscut position. -- Includes: -- Rear roller module support rails; rear of machine enclosed for safety.

$12,560

SELCO - EB 120: CNC Frontload Panel SawSpecifications -- 14.4' (4,400 mm) Overall cutting length & 4.7" (120 mm) max. saw blade projection; 18 HP main & 2.4 HP scoring motor; modular roller rear machine table; side aligning device; (2) longitudinal aligners to accurately position the book of panels on the rear saw table prior to cutting. -- Variable saw carriage travel speed: 0 - 328 FPM; electronically controlled overhead program fence; rack & pinion driven; forward speed: 196 FPM; return speed: 196 FPM.Equipped with: -- (6) Clamps (open up to 122 mm) of which: (3) Closely spaced in crosscut area; the other (3) are at equal distance in rip cut area. -- AC Servo Motor drives on both: Saw carriage and pusher fence. Operator & Machine Control: -- The front-end controlled by PC: Color monitor integrated into a "high-tech look" Operator control panel (which displays cutting dimensions & patterns); panel has virtually unlimited: Cutting pattern storage capacity; self-diagnostic. Data can be input by keyboard or downloaded directly from the office PC. Complete with: -- 2,300 mm Long crosscut fence stroke (side to side); (2) side/crosscut aligners. -- (3) Front mounted air float tables with: Rounded front for moving panel from rip to crosscut position (24" x 79" each). -- Rear of machine partially enclosed for safety.

SHENG-SHING - SDM-25, ...25" Wide Belt Sander1-Head; 24" width cap.; rubber-covered contact roll; approx. 10 HP motor. -- Abrasive belt size 25" x 48" with: Air tensioning & electronic abrasive belt tracking. -- 5-1/2" Max. height opening with: Manual raise & lower; variable feed speed drive. -- Complete with: Magnetic controls & dust outlet.

$1,950

SHENG-SHING - SDM-15 ...Wide Belt Sander (Open Ended)15" Single Head Wide Belt Sander with open end for up to 30 " capacity. -- Sanding Head: 15" Wide (30" cap. with 2-pass); 8" Helically Grooved Rubber Covered Contact Roll with 7.5 HP Drive. -- Features: 0" - 6" Part thickness cap., 2-speed conveyor feed 12 or 16 FPM; 16" x 48" Abrasive belts with air tensioning, pneumatic abrasive belt tracking.

Call for Price

--This machine is in an Auction on exfactoryauctions.com-- SHODA MAXXIM 5' x 10' 2-Head CNC Router, with Vacuum Pump – Seller states that machine was run (1) shift from 2002 - 2006, then only a few days per year since! Specifications: Table size 63” x 122” x 29” H, with 3/4” Thick Top. Travels: X-Axis 133", Y-Axis 73", & Z-Axis 10". Max. machining feed speed 590 IPM. Max. positioning speed for X & Y-Axes 1,180 IPM. Equipped with: Moving single-zone vacuum table, with Extra-hard phenolic surface, Front-to-back configuration. (2) 12 kW (16 HP) - 18,000 RPM BT-30 Air-cooled electro-spindle, with Variable spindle speeds 3,000 - 18,000 RPM, AC Inverter, Dynamic spindle braking, Air/Oil mist lubrication. 16-Position Carousel-type automatic tool changer. Features: All Axes with Extra-large precision contour linear guideways. Closed loop AC Servo drives & Precision ground ball screws. Extended extra heavy-duty bridge for full 5' x 10 table coverage. Centralized lubrication system for all spindle & roller bearings, ball screws & guides. Operator Control: FANUC "SERIES 21i-M" Mobile CNC Control, with 10.4" Display, RS-232 Port, PCMCIA Slot, (3) Axes Simultaneous control, Manual pulse generator, Inch & Metric operation, Feed rate & Spindle speed override, Helical interpolation, Full cutter compensation, Background editing features, EIO/ISO recognition. Foot pedal control. Complete with: 2001 TRAVAINI "1-501V1A-460" 40 HP Vacuum Pump, S/N S1433, with Hour meter reading 17,003 Hrs. (10) Toolholders. Dust Manifold. Dimensions without Safety Rails: 202" x 155" x 110" H. Dimensions of Vacuum Pump: 82" x 36" x 65" H.

Call for Price

SHODA MAXXIM 5' x 10' 2-Head CNC Router, with Vacuum Pump – Seller states that machine was run (1) shift from 2002 - 2006, then only a few days per year since!Specifications: -- Table size 63"; x 122"; x 29"; H, with 3/4"; Thick Top. -- Travels: X-Axis 133", Y-Axis 73", & Z-Axis 10". -- Max. machining feed speed 590 IPM. -- Max. positioning speed for X & Y-Axes 1,180 IPM.Equipped with: -- Moving single-zone vacuum table, with Extra-hard phenolic surface, Front-to-back configuration. -- (2) 12 kW (16 HP) - 18,000 RPM BT-30 Air-cooled electro-spindle, with Variable spindle speeds 3,000 - 18,000 RPM, AC Inverter, Dynamic spindle braking, Air/Oil mist lubrication. -- 16-Position Carousel-type automatic tool changer.Features: -- All Axes with Extra-large precision contour linear guideways. -- Closed loop AC Servo drives & Precision ground ball screws. -- Extended extra heavy-duty bridge for full 5' x 10 table coverage. -- Centralized lubrication system for all spindle & roller bearings, ball screws & guides.Operator Control: -- FANUC "SERIES 21i-M" Mobile CNC Control, with 10.4" Display, RS-232 Port, PCMCIA Slot, (3) Axes Simultaneous control, Manual pulse generator, Inch & Metric operation, Feed rate & Spindle speed override, Helical interpolation, Full cutter compensation, Background editing features, EIO/ISO recognition. -- Foot pedal control.Complete with: -- 2001 TRAVAINI "1-501V1A-460" 40 HP Vacuum Pump, S/N S1433, with Hour meter reading 17,003 Hrs. -- (10) Toolholders. -- Dust Manifold.Dimensions without Safety Rails: 202" x 155" x 110" H.Dimensions of Vacuum Pump: 82" x 36" x 65" H.

$1,400

SHOP FOX - W1812: Planer MoulderSpecifications -- 12" Open-sided Mini Planer/Moulder offers: Smooth moulding & planing. -- 2 HP Motor belt drives head: 7,000 RPM Spindle speed. -- Very smooth operation with: Variable feed rate of 0 - 18 FPM. -- Cutterhead Diameter: 1-1/4". -- Max. material width: 6-3/4"; planes: 7-1/2" wide. -- Easily handles material thickness from: 1/4" to 7-1/2" Max. -- 9" Min. stock length; max. profile depth: 3/4"; max. profile width: 6-3/4". -- Comfortable table working height: 31". Includes -- Sturdy work "stand". -- Controls: On/Off front-mounted.

Call for Price

SHOP FOX W1678 Heavy Duty 26" 2-Head Drum SanderSpecifications: -- Heavy Duty 26" 2-Head Drum Sander. -- 24" Wide thick conveyor belt, similar to the ones used with Wide Belt Sanders. -- (2) drums 6" x 27-3/4". -- Enclosed fabricated steel base with easy access doors. -- 5 HP Single-phase motor that drives both sanding drums. -- 1st Head for coarse; 2nd head for fine sanding. -- Independent adjustment on both heads. -- Variable Speed conveyor , 0.25 HP feed drive. -- 0" - 4-1/4" Thickness cap. with manual hand wheel adjustment. -- (2) Each rubber covered infeed & outfeed rollers. -- (2) Dust outlets and push button magnetic controls.