704-841-2001

Backed with a massive machinery database considered to be “the blue book” of woodworking machinery), EX-FACTORY Auctions provides a complete assessment of your equipment and allows you to interact with the market real-time in our dynamic Online Auction!

Industry

Woodworking

1849 Results Found

704-841-2001

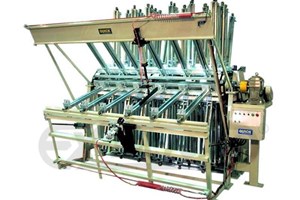

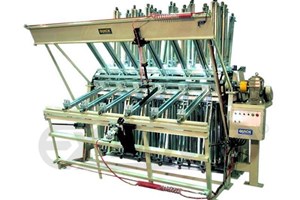

²QUICK 14-Section Pneumatic Clamp Carrier with 10-1/2' width capacity With (8) Standard zinc plated clamps per section (112) clamps total), 38" opening on clamps Standard Features include: -- Clamps jaws are 2-1/2" high x 4-3/4" wide with 1° inward draft to keep stock securely held down. Clamps use 3/4" dia. full-length screws; corrosion resistant, zinc plated, full box frame. For face gluing, Rocking Plates available as optional equipment -- Panel Flattener with easy-to-use controls. -- Pneumatic Clamp Tightener; 3,000 RPM air wrench is 5 to 10 times faster than competitive tighteners; a two-handed, trigger-activated tightener is more confidence-inspiring than the old ergonomically awkward "swing-style" clamp tighteners. Fast tightening and full-length clamp screws eliminate the need for manual adjustment of rear clamp jaws. -- Electric Motor Rotation; push button, automatic cycle with indexing. -- Automatic Rotation Cycle includes the entire sequence; reverse rotation, front-rest out, forward rotation, front-rest in, and lay clamps on front rest. Perfectly! Every time! Complete with: -- Foot levelers, coiled air lines, flexible conduit for electric wires, automatic air line oiler, high-quality urethane finish coating, and toolbox with spare parts & tools. -- A 14-Section Clamp will produce approx. 300 panels

QUICK 6-SECTION, 12-1/2' Wide Pneumatic "Standard" Clamp Carrier: 6-Section Clamp, typically produces (144) high-quality edge glued panels per day (3 panels per section x 6 sections x 8 hours). Equipped with: -- (6) Sections with (9) clamps per section and 12-1/2' width capacity. -- (54) Clamps with 38" opening and 2-1/2" high x 4-3/4" wide jaws with 1° inward draft. Clamps use 3/4" dia. full-length screws; corrosion resistant, zinc plated, full box frame. -- Rocker Plates are available as optional equipment for face gluing. Features: -- Semi-automatic electric motor drive. -- Pneumatic Panel Flattener for 10-1/2' wide Carrier with easy-to-use controls. -- Pneumatic Clamp Tightener with a 3,000 RPM air wrench is (5 -10) times faster than competitive tighteners; the 2-handed, trigger-activated tightener is more confidence-inspiring than the older, ergonomically awkward "swing-style" clamp tighteners. -- Fast tightening and full-length clamp screws eliminate the need for manual adjustment of rear clamp jaws. Complete with: -- Foot levelers, coiled air lines, flexible conduit for electric wires, and automatic air line oiler; -- High-quality Urethane finish coating, and tool box with spare parts & tools.Floor space requirement: 195"W X 125" H X 127"D

QUICK 6-SECTION, 10'-1/2' Wide Pneumatic "Standard" Clamp Carrier: 6-Section Clamp typically produces (48) high quality edge glued panels per day (3 panels per section x 6 sections x 8 hours). Equipped with: -- (6) Sections with (8) clamps per section and 10-1/2' width capacity. -- (48) Clamps with 50" opening and 2-1/2" high x 4-3/4" wide jaws with 1° inward draft. Clamps use 3/4" dia. full-length screws; corrosion resistant, zinc plated, full box frame. Features: -- Electric motor drive. -- Pneumatic Panel Flattener for 10-1/2' wide Carrier with easy to use controls. -- Pneumatic Clamp Tightener with 3,000 RPM air wrench is (5 -10) times faster than competitive tighteners; 2-handed, trigger activated tightener is more confidence inspiring than the older, ergonomically awkward "swing-style" clamp tighteners. -- Fast tightening and full-length clamp screws eliminate need for manual adjustment of rear clamp jaws. Complete with: -- Foot levelers, coiled air lines, flexible conduit for electric wires, automatic air line oiler, high quality Urethane finish coating, and tool box with spare parts & tools. --

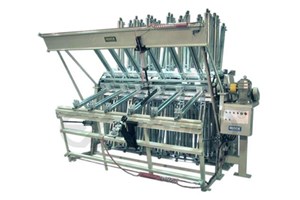

Quick Heavy Duty Pneumatic Clamp Carrier with 20-sections and 12-1/2' width capacity. -- (8) Heavy Duty zinc plated clamps per section for 10 section, clamp opening 44" -- (10) Heavy Duty zinc plated clamps per section for 10 section, clamp opening 44" -- Includes 180 clamps with 44" openings and 3.5" high x 4-3/4" wide jaws with 1° inward draft. -- Pneumatic overhead panel flattener along with tightener -- Pneumatic panel flattener for second operator -- Semi-Automatic Pneumatic clamp tightener . -- Semi-Automatic panel tightener for second operator -- Single button automatic electric motor rotation cycle with indexing. -- Heavy Duty frame with 3" diameter shafts and 6" I-beam legs. -- Includes foot levelers, coiled air lines, flexible conduit for electric wires, automatic air line oiler, high quality urethane finish coating and tool box with spare parts & tools.

QUICK 14-Section Heavy Duty Hydraulic Clamp Carrier with 20-1/2' width capacity With (16) Standard zinc plated clamps per section (224) clamps total), 38" opening on clamps Standard Features include: -- Clamps jaws are 3-1/2" high x 4-3/4" wide with 1° inward draft to keep stock securely held down. Clamps use 3/4" dia. full-length screws; corrosion resistant, zinc plated, full box frame. For face gluing, Rocking Plates available as optional equipment -- Pneumatic Panel Flattener with easy to use controls. -- Pneumatic panel flattener for second operator -- Hydraulic Clamp Tightener; 3,000 RPM air wrench is 5 to 10 times faster than competitive tighteners; two-handed, trigger activated tightener is more confidence inspiring than the old ergonomically awkward "swing-style" clamp tighteners. Fast tightening and full-length clamp screws eliminate need for manual adjustment of rear clamp jaws. -- Hydraulic clamp tightener for second operator -- Electric Motor Rotation; push button, automatic cycle with indexing. Automatic Rotation Cycle includes entire sequence; reverse rotation, front-rest out, forward rotation, front-rest in, and lay clamps on front rest. Perfectly! Every time! Complete with:Foot levelers, coiled air lines, flexible conduit for electric wires, automatic air line oiler, high quality urethane finish coating, and tool box with spare parts & tools. 14-Section Clamp will produce 300 panels

Quick Heavy Duty 14-Section Hydraulic Clamp Carrier, 16-1/2' Wide -- 14-Section Clamp Carrier 16-1/2' width cap.. -- (12) Heavy Duty zinc plated clamps per section for (168) total clamps. -- 38" opening on clamps; jaw sizes on clamps are 3-1/2" high x 4-3/4" wide with 1° inward draft. Equipped with: -- Dual Overhead Pneumatic Panel Flatteners for (2) operators -- Dual Hydraulic Clamp Tighteners for (2) operators -- Automatic Electric Motor Rotation with Indexing. -- Standard features include: Foot levelers, coiled air lines where used and flexible conduit for wires.

QUICK 20 Section 16.5' Heavy Duty Clamp Carrier Specifications: -- 20-Section Thick Stock Pneumatic Clamp Carrier; 16-1/2' width cap.; -- (12) Clamps, each with 3 1/2" high jaws and 44" clamp opening for a total of (240) clamps. -- All clamps are heavy duty type; zinc plated and with 1° inward draftEquipped with: -- Dual operator package with (2) pneumatic overhead panel flatteners, -- (2) Pneumatic clamp tighteners. -- Semi-automatic rotation via electric motor drive and separate buttons for Front Rest Out, Rotate Reverse, Rotate Forward and Front Rest In.Standard features: -- Heavy-duty thick stock frame with 3" dia. shafts and 6" I-beam legs; -- Foot levelers, coiled air lines, flexible conduit for electric wires, automatic air line oiler, high-quality urethane finish coating, and toolbox with maintenance tools.

QUICK F-CGAP-20-11-17 20" Wide Conveyorized Glue Applicator -- 20" Conveyorized Glue Applicator, 20" wide grooved rubber glue applicator roll and holddown roller with stainless steel doctor blade and glue reservoir.Features: -- Easy adjustment or removal of doctor blade, 30' overall length. -- 11' Infeed before the glue roller . -- 17' Outfeed conveyor. Equipped with: -- Heavy Duty 0.25 HP motor drive for slat-type conveyor and glue roll, limit switch with wand for automatically stopping the slat bed conveyor when stock reaches the Clamp Carrier, adjustable safety slip clutch. Complete with: -- Foot levelers. -- Heavy Duty crossbars. -- Chain guard, high quality anti-stick Urethane finish. -- Owner & operator's manuals.OPTION:Hold Down roll for face gluing 20" wide: $ 700 additional

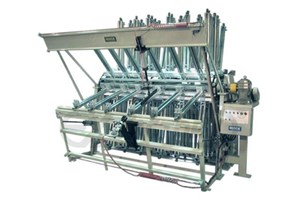

QUICK 20 Section Heavy Duty Pneumatic Clamp Carrier: -- Clamp Carrier: (20) Sections with 8-1/2' width cap., (6) heavy duty zinc plated clamps per section (120 clamps total), 44" opening on clamps (other lengths available). -- Clamps jaws are 3-1/2" high x 4-3/4" wide with 1° inward draft to keep stock securely held down. Clamps use 3/4" dia. full-length screws; corrosion resistant, zinc plated, full box frame. -- For face gluing, Rocking Plates available as optional equipment. -- Equipped with: Panel Flattener with easy to use controls. -- Pneumatic Clamp Tightener; 3,000 RPM air wrench is 5 to 10 times faster than competitive tighteners; two-handed, trigger activated tightener is more confidence inspiring than the old ergonomically awkward "swing-style" clamp tighteners. Fast tightening and full-length clamp screws eliminate need for manual adjustment of rear clamp jaws. -- Electric Motor Rotation: Push button, automatic cycle with indexing. Automatic Rotation Cycle includes entire sequence; reverse rotation, front-rest out, forward rotation, front-rest in, and lay clamps on front rest. Perfectly! Every time! -- Complete with & Includes: Foot levelers, coiled air lines, flexible conduit for electric wires, automatic air line oiler, high quality urethane finish coating, and tool box with spare parts & tools.NOTE: 20 Section machine can produce up to (500) panels per shift!

QUICK 6-Section Pneumatic Clamp Carrier with 20-1/2' width cap. & Dual Operator's Stations, -- (16) Heavy Duty zinc plated clamps per section (96) clamps total), 50" opening on clamps. Jaw sizes of clamps is 3-1/2" high x 4-3/4" wide, with 1° inward draft. Equipped with DUAL OPERATOR'S STATIONS including: -- (2) Pneumatic overhead panel flatteners, -- (2) Pneumatic clamp tighteners -- Semi-automatic rotation via electric motor drive; with separate buttons for Front Rest Out, Rotate Reverse, Rotate Forward, and Front Rest In.Standard Supply includes: -- Foot levelers, coiled air lines, flexible conduit for electric wires, automatic air line oiler, high-quality urethane finish coating, and toolbox with spare parts & tools.

$3,750

SAWSTOP ICS 73230 Table Saw w/Famous Safety "Stop Feature" & New Sliding Crosscut Table.10" Blade cap., 7-1/2 HP - 3,450 RPM motor, 3-1/8" depth of cut @ 0°, 2-1/4" depth of cut @ 45°, 13/16" max. dado width, 5/8" arbor dia, 30"; FB x 24"; LR Table, with 45° Left tilt, & 10"; Left & Right extensions. -- FEATURES: Enclosed cabinet, heavy-duty belt drive, cast iron trunnions, and SAWSTOPS's revolutionary flesh detecting safety mechanism. -- Includes: Rip fence with 52" Right & 12" Left Rip cap., side support table and laminated top, 4" Dust collection port, magnetic contractor motor control, main power switch with removable lock-out key, New SAWSTOP "TSA-SA48" 48" Sliding Crosscut Table, & Accessories (As pictured).Actual model ICS 73230.

SCHEER Veneer Panel Saw. -- General data: 122" Cutting length, 1-1/2" depth of cut, 3/4" - 42" max. back fence cap. with extension fingers, 5 HP arbor motor; saw carriage travels on hardened & ground ways. -- Equipped with: Manual operated saw carriage with hand crank Full-width rear fence with support, hand wheel operated rear fence with scale & arrow readout for positioning. -- Lockable fence at cutting position, fence line also pivots up to permit end trimming against the left guide fence. - Pneumatically controlled hold-down pressure beam. -- Complete with: Push button control and dust collection chute with channel in table base.NOTE: machine is currently in storage and can not be test run, we are told it was on working condition when placed into storage

SCHELLING FM-430/410 CNC Front Load Panel SawSpecifications & Features: 169" (4292 mm) Cutting length & 165.3" (4,200 mm) pull back, 3.75" (95 mm) max. saw blade projection; 25 HP (19 kW) 4,100 RPM main & 3.4 HP (2.5 kW) 5,600 RPM scoring motor. -- Equipped with: Variable saw carriage travel speed from 0 - 278.8 FPM (85 MPM), constant return of 278 FPM (85 MPM). -- Electronically controlled overhead program fence with rack & pinion driven on both sides; forward speed from 0 - 278 FPM (85 MPM), return speed of 278.8 FPM (85 MPM); equipped with (8) gripper clamps (open up to 5" (130 mm). -- Features: SCHELLING "COMPOSER" IBM-AT Compatible Computer Control; aftermarket color monitor (displays cutting dimensions and patterns w/moving graphics) , self-diagnostic, data input by keyboard; onboard optimization program. -- Complete with: 2-3/4" to 87" (2,200 mm) Long side/cross-cut aligning zone, (1) aligner in front & (1) behind the cut line. -- (3) Front mounted air float tables for moving panel from rip section to the cross-cut section, (2) movable and (1) fixed; each with their own blower. -- Rear of machine fully enclosed for safety with man-height sheet metal panels & wire screen windows. T

--In Auction--Starting bid: $100-- Schuetz Tool Bladder Press Specifications: (2) Shuttle tables, approx. 55” x 106” press capacity. Hot air design with 3mm silicone membrane to press veneer into profile, typical cycle time 3 minutes using proper glue that sets at 200°F. Can use PVA which would extend cycle time to approx. 15 > 45 minutes depending on the actual glue mix used to achieve 80%+ cure strength. Includes Hydraulic Pump. SPECIAL NOTE: Fully operational, however, need 4 or 5 heating rods replaced, new rod parts are included for you to install ( don't have the capability to remove them). The current average operational temperature is 150° F. NOTE: Above specs are taken from literature and thought to be accurate. As always please take advantage of the inspection period to verify. Items seen in the background are NOT a part of this Lot.

Call for Price

Schuetz Tool Bladder Press Specifications: (2) Shuttle tables, approx. 55” x 106” press capacity. Hot air design with 3mm silicone membrane to press veneer into profile, typical cycle time 3 minutes using proper glue that sets at 200°F. Can use PVA which would extend cycle time to approx. 15 > 45 minutes depending on the actual glue mix used to achieve 80%+ cure strength. Includes Hydraulic Pump. SPECIAL NOTE: Fully operational, however, need 4 or 5 heating rods replaced, new rod parts are included for you to install ( don't have the capability to remove them). The current average operational temperature is 150° F. NOTE: Above specs are taken from literature and thought to be accurate. As always please take advantage of the inspection period to verify. Items seen in the background are NOT a part of this Lot.

Call for Price

SCHUTTE BUFFALO - Model WA16L, ... HammermillModel# WA16L, 3500 RPM, with filtration system and multiple grates for destruction sizes. -- It also includes Electrical panel. -- This system is apart and palletized. All you have to do is pick it up and transport it to you. -- System was in perfect working order when it was taken apart and palletized for transport. -- The system is perfect for the destruction of computer hard drives and different types of media.

$7,700

SCM - S520 E, ...Planer Specifications: -- 20" Width cap.; 9 HP main motor; 4-3/4" dia. 4-knife TERSA cutterhead at 4,500 RPM. -- 1/8" - 9-1/4" Powered opening with digital readout for fine adjustment; max. depth of cut 5/16"; 10" min. length of workpiece. -- (4) Feed speeds: 20 - 33 - 43 & 56 FPM; table size 20-3/4" x 39".Equipped with: -- Chip breaker; sectional grooved infeed & solid outfeed rollers; (2) adjustable bed rollers. -- Complete with: Magnetic starter & shaving hood.

$4,460

SCM - S 52, ...Straight Knife Planer20" Width cap.; knife cutterhead; 9 HP main motor (approx.); 1/8" to 9-1/4" motorized opening with mechanical digital readout; max. depth of cut 5/16"; 10" min. length of workpiece; (4) feed speeds at: 21 - 32 - 42 & 55 FPM; table size: 20-1/2" x 33-1/4". -- Equipped with: Chip breaker; sectional grooved infeed & solid outfeed roller.

$4,410

20" (520 mm) Width cap.7,5 HP (5,5 kW) main motor ÷4-knife cutterhead÷1/8" to 9-1/2" (3 - 240 mm) ÷motorized opening mechanical scale for bed position max. depth of cut 5/16"÷10" min. length of workpiece ÷(4) feed speeds at 18/30/39/51 FPM (6/10/13/17 m/min.)÷table size 20-3/4" x 33-1/4". ÷Includes: Knife sharpening attachment ÷ Equipped with: Chip-breaker, sectional grooved infeed & solid outfeed roller.

$23,090

SCM SANDYA - 40 M3 135, ...3-Head Wide Belt Sander 52" Width cap. Drum, Drum, Combination HeadHead Configuration:1st Head: Steel Contact 22 kW Pneumatic blowdown and alignment.2nd Head : Rubber Contact 18.5 kW Pneumatic blowdown and alignment.3rd Head: Combination Platen 15 kW Pneumatic blowdown and alignment.Note:The SCM sander does not have a brush. After the 3rd head, it has this pneumatic blow-off bar with multiple blow-offs running the length of the sanders width. Sander can be seen under power if needed.Specifications: -- 53" x 103" Abrasive belts with electronic tracking. -- All heads with abrasive belt grit compensation. -- Conveyor belt feed with dual feed speed, 5 HP motor. -- Automatic part thickness adjustment. -- Motorized thickness opening via (4) precision conveyor bed jacks with LED readout. --0" - 7-7/8" opening. -- Equipped with & Features -- Outfeed rubber covered holddown rolls or shoes on all heads. -- Motor load meters. --Infeed and outfeed conveyor extensions. -- WYE-DELTA soft start.Note: The SANDYA model "40" is more or less the same as the SANDYA "30" but more Heavy Duty.