704-841-2001

Backed with a massive machinery database considered to be “the blue book” of woodworking machinery), EX-FACTORY Auctions provides a complete assessment of your equipment and allows you to interact with the market real-time in our dynamic Online Auction!

2032 Results Found

704-841-2001

$12,950

BUSELLATO B1CNC CNC MACHINING CENTER (UNIVERSAL): -- Specifications: Design Type: Cantilever Style, 49" x 120" universal phenolic machine table, multizone "Universal" vacuum table for use with pods. -- Equipped with:(1) 10 HP ISO 30 Type ATC spindle; variable speed from 3,000 - 18,000 RPM; (7) position side tool magazine; (1) Multispindle boring block (7-vertical, 4-horizontal) with an X-axis grooving Saw. -- PC-Based ControlWith "Windows 2000 Professional", GENESIS EVOLUTION programming software, Rail plan for pod location software, Autolink DXF conversion software, Autobar labeling software, Gencode barcode reading software. -- Complete with:(1) 80 Cubic meter rotary vane Vacuum Pump; assorted tooling; documentation; manuals and applicable software media.NOTE: This machine has very low usage and was used more like a Hobby/R+D CNC Machining Center by the owner.INCLUDES: -- CORAL - CA/3C Dust Collector; (3) canvas filter Bags; (3) HD plastic Collection Bags; 10" dia. intake flange; 3,105 CFM; 5.5 HP motor, 3/220/440 Volt; complete with on/off starter.

$15,000

BUSELLATO JET 3006 FLAT TABLE MACHINE (W/ATC/BORING): -- Specifications:4' x 10' "Matrix" grid phenolic surface table for "Nested Based Manufacturing". -- Working cap.:"X" Axis is 121.2" (3,080 mm), "Y" axis is 49.2" (1,250 mm), "Z" axis stroke is 8.1" (205 mm); max. panel thickness is 5.9" (140 mm); -- Positioning Speed:Max. programmable speed: "X" & "Y" axis is 328 FPM (100 MPM), "Z" axis is 111 FPM (34 MPM). -- Work Table:(2) independent working areas with locating stop pins on the front & rear - LH & RH sides for positioning of parts on the worktable; prepared for (optional) elevated pods that allow profile & horizontal machining. -- Boring Unit:(16) Independent vertical boring spindles with (8) spindles in "X" axis & (8) spindles in "Y" axis, (4) horizontal spindles with (1+1) spindle in "X" axis & (1+1) in "Y" axis; 120 mm "X" axis grooving saw; inverter controlled variable spindle speed up to 4,000 RPM. -- Machining:(1) 14 HP (10 kW) Vertical electro-spindle router with HSK-F63 adaptor, inverter driven 1,000 - 24,000 RPM with max. torque from 12,000 - 24,000 RPM;(1) 10-position "Ride Along" automatic rotary tool changer for "on-the-fly" ATC. -- Operator & Machine Control:"PC" Front-End with "GENESIS" + Windows '95, '98 & NT operating system; 32-bit Pentium - 400 MHz processor; 4 GB hard drive,15" Color monitor, international keyboard, soft touch keypad & industrial mouse, RS-232 serial port and (1) 1.44 MB floppy disk drive.Real-time multitask processing; programs can be transferred via diskette or downloading by wire is possible;built-in 1,500 W air conditioner for constant temperature & dust-free environment. -- GENESIS Operating system for real-time multitask processing; programs can be transferred via diskette or downloaded by wire; -- Complete with:(1) 25 HP Dekker V-max vacuum pump, automatic "forced" lubrication system for guides & ball screw; emergency stop rope & pressure sensitive safety mats that will instantly place machine in "pause cycle" when stepped on; sound absorbing protective head enclosure with debris curtain around bottom edge. built-in 1,500 W air conditioner for constant temperature & dust-free environment - Complies with CE norm specifications. -- Actual Model is BUSELLATO JET 3006 RT

BUSELLATO - Junior 60 4-Y, ...CNC Machining CenterControls & Router Head Drive Systems upgraded in 2015Specifications: Max. operating field strokes: X-Axis is 3,200 mm (125.98"); Y-axis is 1,220 mm (48"); Z-axis is 60 mm (2.4"); max. positioning speed on the X-axis is 196 FPM, Y-axis is 164 FPM, and Z-axis is 33 FPM.Equipped with: Boring head with: (27) Independently selectable vertical spindles for face boring; driven by a 4 HP motor; (11) of the spindles are in the Y-axis and (16) spindles are in the X-axis (one shared spindle in X-/Y-axis).Additionally equipped with: (2) 2-Spindle horizontal boring heads: (2) Opposing in X-axis; 64 mm pitch for boring right & left sides. -- (1) 10 HP RH/LH Router and (1) 9.5 HP Router (0 - 18,000 RPM) by solid-state inverter; 5 HP grooving saw. Automatic Tool Changer with: 5-Position tool holder and ISO-30 adapters.Worktable with: (8) Panel supports; ea. with: (3) Vacuum cups, (2) independent work zones, (4) adj. lateral reference stops, (4) center reference stops. -- BUSELLATO CNC Controls.Includes: 14" Color monitor, (2) RS-232 ports, (1) RS-242 serial port, keyboard, floppy & hard drive systems for data management; all built into a protective cabinet enclosure; front & rear photo eyes for operator safety; (2) TRAVAINI EO Vacuum Pumps.NOTE: Seller can help coordinate logistics and loading of machine.

$10,200

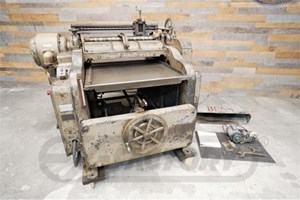

BUSS - DL 30" x 8", ...Heavy-Duty Wood Planer with GrinderModel "DL" bed capacity: 30" W x 65" L x 8" H,Specifications -- (2) Large steel support rollers on bed; upper area: (1) Steel roller. -- (1) Cutterhead with: (4) Knives; (1) grip through roller. -- Heavy-Duty spring tension adjustment on top of machine. -- (2) 15 HP - 3 PH motors; one connected to 20-ratio gear reducer, variable feed speed drive; the other connected to the cutterhead system. -- Upper cross frame attachment for Knife Grinder System (comes with the Grinder).Equipped with & Features -- Oil cup & grease fitting lube system. -- Power raising and lowering of the Planer bed.

$6,950

BUSS M 4L 30" STRAIGHT KNIFE PLANER30" X 8" Cap., 20 HP direct drive top motor, 1.5 - 2 HP for dual feed speed, 4-knife round top cutterhead, sectional infeed rolls and chipbreaker. Complete with: Shaving hood, magnetic starters.

--MAKE OFFER!--EXCELLENT CONDITION!-- BÜTFERING SWT134/RRC 1100 mm (43.31") 3-Head Wide Belt Sander, with Combination Head Specifications: Suitable for sanding of veneered parts in 1 or 2 passes with segmented pad only & Thickness tolerance compensation up to 1 mm (0.04”), Suitable for sanding of solid wood & wood based materials in single pass with 3 grit sequence. Thickness cap. 3 mm - 160 mm (0.19” - 6.30"). Variable feed speeds 2.5 - 13 MPM (8.5 - 42 FPM). Equipped with: 1st Head: 160 mm (6.30”) Dia. Grooved steel contact roll, with Grit size compensation, Automatic positioning for calibrating, & 15 kW (20 HP) - 2,930 RPM Motor with Electric braking. 2nd Head: 160 mm (6.30”) Dia. 85° Shore Grooved rubber-covered contact roll, with Grit size compensation, Automatic positioning for calibrating, & 15 kW (20 HP) - 2,930 RPM Motor with Electric braking. 3rd Head: Combination head, with 60 mm (6.30”) Dia. 65° Shore Grooved rubber-covered contact roll, 3-3/4" Dia. Smooth steel contact roll, 3-1/8” W Electronically-controlled segmented pad finishing platen with 35 mm (1.38”) W Segments, & 18 kW (15 HP) Motor with Electric braking. 1-7/8” Dia. Rubber-covered roller & spring-loaded segmented nylon rollers on infeed & 1-7/8” Dia. Rubber-covered spring-loaded hold-down rollers between heads & after 3rd head. 1,120 mm x 1,900 mm (44.09" x 74.80") Abrasive belts, with Electronic oscillation. 43-1/4” W x 5’ L Feed belt, with 1.3 kW (1-3/4 HP) Feed motor with Frequency inverter, 44” W x 8” L 2-Roll Infeed Extension, & Automatic conveyor belt tracking. Power raising of conveyor bed, with Automatic thickness adjustment & Over thickness Protection. LCD Touchscreen control, with 5-1/2” Display, & Motor load meters. Complete with: Original Production Instructions. CURRENCY NOTE: Negotiable Price is listed in U.S. Dollars.

BÜTFERING SWT 335-RLL 3-Head Wide Belt Sander,53" Width cap. Drum, Drum, Combination HeadHead Configuration1st Head: Steel Profiled Contact Roller 21.5 KW (28.83 HP)2nd Head: Rubber Profiled Contact Roller 17.4 KW (23.37 HP)3rd Head: Combination Head: Contact Roller & Air Cushion Sanding Pad/Platen Head 17.4 KW (23.37 HP)4th station: Panel Cleaning BrushSpecifications -- 1st Head: Steel contact roll, 240 mm (9-1/2") dia., abrasive belt speed 18 m/sec (59 FPS), driven by 22 kW (30 HP) motor. -- 2nd Head: Rubber covered contact roll, 65 Shore hardness, 240 mm (9-1/2") dia., abrasive belt speed 18 m/sec (59 FPS), driven by 15 kW (20 HP) motor. -- 3rd Head: Combination head consisting of Contact roller 55 Shore hardness, 140 mm (5,5") dia. and Air cushioned polishing platen with jump control for leading & trailing edges. Abrasive belt speed 12 MPS (39 FPM), driven by 15 kW (20 HP) motor. -- Outfeed rotary panel cleaning brush. -- All heads use 1,400 x 2,620 mm (54" x 103") abrasive belts. Electronic abrasive belt tracking. Air jet abrasive belt cleaner on head # 2.Feed system: -- Conveyor belt feed with variable feed speed from 2,5 - 13 m/min (8 - 42 FPM). -- Vacuum table with internal suction fan and motor 5,5 kW (7,5 HP). -- Part thickness 3 - 160 mm (1.2" - 6.3").Equipped with & Features -- Motorized thickness adjustment with LED readout. -- Constant pass line of conveyor bed 900 mm (35"). -- Automatic electronic conveyor belt tracking, in & outfeed spring loaded rubberized hold-down rolls. -- Automatic part thickness setting. Complete with: -- Infeed panel "over-thickness" sensor, in & outfeed emergency stops, safety interlocks on all doors. --Telescopic infeed roller conveyor extension, fold away outfeed table 900 mm (35"). -- Motor load meters, and main motor electronic brakes. -- Operator panel with joystick and multi-function readout for thickness, feed speed etc.Full Load Amps: 150 FLA at 460 VoltsCompressed Air: 55 cfm @ 90 PSI RequiredTotal CFM Required 5,365Actual model is BÜTFERING SWT 335-RLL 3-Head Wide Belt Sander

BÜTFERING SWT134/RRC 1100 mm (43.31") 3-Head Wide Belt Sander, with Combination HeadSpecifications: -- Suitable for sanding of veneered parts in 1 or 2 passes with segmented pad only & Thickness tolerance compensation up to 1 mm (0.04";), Suitable for sanding of solid wood & wood based materials in single pass with 3 grit sequence. -- Thickness cap. 3 mm - 160 mm (0.19"; - 6.30"). -- Variable feed speeds 2.5 - 13 MPM (8.5 - 42 FPM).Equipped with: -- 1st Head: 160 mm (6.30";) Dia. Grooved steel contact roll, with Grit size compensation, Automatic positioning for calibrating, & 15 kW (20 HP) - 2,930 RPM Motor with Electric braking. -- 2nd Head: 160 mm (6.30";) Dia. 85° Shore Grooved rubber-covered contact roll, with Grit size compensation, Automatic positioning for calibrating, & 15 kW (20 HP) - 2,930 RPM Motor with Electric braking. -- 3rd Head: Combination head, with 60 mm (6.30";) Dia. 65° Shore Grooved rubber-covered contact roll, 3-3/4" Dia. Smooth steel contact roll, 3-1/8"; W Electronically-controlled segmented pad finishing platen with 35 mm (1.38";) W Segments, & 18 kW (15 HP) Motor with Electric braking. -- 1-7/8"; Dia. Rubber-covered roller & spring-loaded segmented nylon rollers on infeed & 1-7/8"; Dia. Rubber-covered spring-loaded hold-down rollers between heads & after 3rd head. -- 1,120 mm x 1,900 mm (44.09" x 74.80") Abrasive belts, with Electronic oscillation. -- 43-1/4"; W x 5’ L Feed belt, with 1.3 kW (1-3/4 HP) Feed motor with Frequency inverter, 44"; W x 8"; L 2-Roll Infeed Extension, & Automatic conveyor belt tracking. -- Power raising of conveyor bed, with Automatic thickness adjustment & Over thickness Protection. -- LCD Touchscreen control, with 5-1/2"; Display, & Motor load meters.Complete with: -- Original Production Instructions.

Homag Sander Butfering W300 SWT345/QCUH (4) Heads wide belt sander53" Width cap. Cross belt , Combi head Electronic platen, Universal oscillating brushing cups, Chevron super-finish head Electronic platen, Cleaning brushHead Configuration1st Head: processing unit Cross belt Electronic platen2nd Head: Processing unit Combi head Electronic platen3rd Head: Processing unit Universal oscillating brushing cups (includes additional brass wire 300mm drum and 300mm Tynex Drum in carts never used4th Head: Processing unit Chevron super-finish head Electronic platen5th Station Head cleaning brushSpecifications -- Air jet blowers -- Integrated vacuum -- Bed width 53"; -- Includes AC unit -- Digital calliper -- About 30 belts different grit sizes -- All heads are program controlled5’ out feed table with interoll rubber rollersEquipped with & Features -- Custom metal fencing -- 6 custom metal belt racks -- Voltage 460 -- Machine commissioned June 2021 -- Sellerwill include preparing the machine for shipping and loading NOTE Reason for sale. Changes in manufacturing process.

$27,500

Bütfering SWT 124 RC Wide Belt Sander (2) Heads43" Width cap. Drum, Combination HeadBütfering SWT 124 RL Features: --Touch Screen display and control. -- Capacity of (125) programs. -- Conveyor speed is controlled within the program. -- Controls the number of sanding heads activated. -- Controls use of sanding pad or contact roller on combination heads. -- Controls thickness of work piece. -- Controls air jet belt cleaning on or off ( only on models with this feature). -- Error message display including safety functions. -- Displays in mm or decimal inches. -- Hour meter display. -- Conveyor table mounted on four heavy duty jack screws. -- Automatic conveyor belt tracking. -- Electronic belt oscillation system. -- Electronic motor braking system. -- Over thickness protection system. -- Safety interlocks on all access doors. -- In feed roller table. -- Emergency stops at in feed and out-feed locations.Head Configuration:1st Head: Contact roller head located in position #1 includes:160 mm diameter steel profile contact roller. -- Automatic height positioning -- Grit compensation -- 20 HP motor -- Cutting speed is 60 FPS.2nd Head: Combination head located in position #2 includes: -- 65 shore profiled rubber contact drum --Automatic height positioning -- Air cushion sanding pad with rise and fall timing -- 18 HP motor -- Cutting speed is 60 FPSSpecifications: -- Working width 1,100 mm (43";) -- Abrasive Belt width 1120 mm (44";) -- Abrasive Belt length 1,900 mm (75";) -- Work piece thickness min. 3 mm ( 1/8"; ) -- Work piece thickness max. 160 mm (6-3/8";) -- Variable conveyor speed 8 - 42 FPM; Feed motor 1 HP -- Contact Roller - Head #1 20 HP, 60 FPS belt speed. -- Combination- Head #2 18 HP, 60 FPS belt speed.Utilities: -- Total power required 28 kW. -- Dust collection requirements 1500 CFM; -- Dust outlet – head #1 160 mm ( 6.25 "; ) -- Dust outlet – head #2 160 mm ( 6.25 "; ). -- Compressed air requirements 90 PSI; Air consumption per cycle 4 CFM; Machine net weight 3960 Lbs.

$26,500

BÜTFERING SGO 211 RK Wide Belt Sander, 2-Head,(43") Working width, equipped with (1) Contact Roller and (1) Combination Head consisting of Contact Roller & Finishing Platen.Head Configuration;1st Head: Rubber contact roller 160 mm (6.3") with 15 kW (20 HP) motor.2nd Head: Combination head with rubber covered contact roller and finishing platen, not segmented, 11 kW (15 HP) motor.Specifications: -- Both heads use 1,120 x 1,900 mm (43" x 75") abrasive belts with electronic abrasive belt tracking. -- Feed system: Conveyor belt feed with variable feed speed 2,6 - 13 m/min (8,5 - 42 FPM), 1,1 kW (1.5 HP) feed drive, auto belt tracking. Part thickness 3 - 160 mm (0.1 - 6.3"). Automatic motorized part thickness adjustment with 0,1 mm LED readout.Equipped with and Features -- Electronic emergency brakes on sanding head motors. -- Infeed emergency stop. -- Motor load meters for supervision of stock removal. -- Roller table extension at infeed. -- Emergency stops at in & outfeed end—automatic star/delta starters.

$499,000

C.R ONSRUD MODEL 615DG24H8 "Dual Gantry Series" CNC router with ATC Multi spindles:5' X 51' working table with Multi spindles and Dual Gantry aluminum non-vacuum table. -- Features:Dual Gantry each with (4) spindles, each gantry has its own 12 position hide away tool changer. -- Thermal Heat Treated:Stress Relieved, & Normalized One-Piece, Steel Frame Base, & Thermal Heat Treated, Stress Relieved, & Normalized Steel Bridge; Dual Support, Dual Drive, Moving Gantry, Fixed Table Design with standard 2,500"; per minute machining speed, full 3-D capability, precision ball screw drives for Z & Y axis, case-hardened, precision ground, helical rack & pinion drives for X axis with forced-air continuous rack cleansing system & anti-contamination shielding, precision linear profile guide ways, centralized manual lubrication system, 11-inches of Z stroke - 14"; under bridge clearance & 11"; Z axis stroke.. -- Spindles:Total of (8), (4) per gantry, 18kW, 24HP "QTC" – 24,000 RPM Liquid cooled Long Nose Spindle w/ HSK-63F Spindle Taper, fully programmable & reversible, variable speed, liquid-cooled, quick-change spindle, capable of routing, drilling and ridged tapping, programmable feed rates w/override capability supported with a 12 hideaway tool changer on each gantry total of 24, Automatic Oil Mist Lubricator for each spindle. -- Spindle adjustments:Servo Adjustment of Spindle Center Distance. -- Controls:(2) FANUC 31i-B5 Machine Controller With Integrated PC Interface one for each gantry Fanuc 31i-B5 is Industrial CNC Machine Controller with Fanuc Panel-i HMI w/High Res touch screen. Includes: Network capability, adds Larger FANUC Digital Drives & Servos. Includes Full remote diagnostic troubleshooting capabilities. -- Complete with:Assorted tool holders, centralized grease lubrication on Multi-Head, 63kVA Isolation Transformer, FANUC MPG Handheld Remote Jog Pendant, and manuals. -- Machine floor space required 64' by 14' 5"

CABLE MANAGEMENT - CMSHSS-100, ...Single Shaft ShredderSpecifications: --Rotor Speed: 60 - 80 RPM --Rotor diameter: 15-3/4″ --Rotor blades: 45 + 4 --Static blades: 2 + 2 --Ram travel: 32″ --Discharge height: 52″ --Screen diameter (holes): 1-1/2″ --Motor power: 100 HP --Hydraulic Power: 5 HP --Chamber size: 42″ x 39″ --Overall dimension: 110″ x 78″ x 82″ --Approx. weight: 9,500 LbsIncludes: Spare Parts

Call for Price

CALPE TH5-1600 Heavy-Duty High-Production, Fully Automatic CNC Lathe: General Description: -- Multi-Spindle cutting simultaneously, (5) spindles using V-type gouge knives. -- 63" (1,600 mm) Max. distance between centers; 5-1/2" (140 mm) max. swing diameter between spindles. -- CNC Controlled with 2.95" (75 mm) travel for depth of cut. Motors/Speeds: -- Servo controlled CNC drives: -- CNC controlled electronic variable speed head drives the movement of the (5) gouge tools. -- CNC controlled feed speed carriage, variable up to 50 FPM (15 MPM). -- (1) Head stock variable speed drive for the (5) spindles, up to 6,000 RPM, approx 10 HP. -- Fast return travel of up to 590 IPM (15,000 mm/Min). 2 HP approx hydraulic drive -- Loading device & tail stock powered by hydraulic pump with 2 HP - 1,750 RPM motor; No. 5 Morse taper on main spindle shaft. Features: -- Automatic loading & unloading device; carriage mounted with linear guides providing high precision movement. -- Full CNC controller with on-screen CAD programming for all products.Matching CALPE L6-1600, record number LC-010996 spindle sander is available at additional cost at same facility.

Call for Price

CALPE L6-1600 Spindle Sander with Hopper Feed. -- (6) Spindles, semi-automatic sanding machine; distance between centers 63", 6-3/16" max sanding diameter, capable of sanding 1800 spindles per hour. -- 4 HP - 1,800 RPM head motor, (5) sandpaper holders, each for different grits, 4000-3200-2200-850 RPM head spindle speeds. Copier unit that follows all contours. -- Oscillating sanding units & stationary pick up of part. -- NOTE: This sander was running with lathe on our record number LC-010811 and owner prefers to sell at the same time.

CAM-WOOD TRS 0012, Straight Line Rip-SawSpecifications: -- Max. cutting depth 3-3/4". -- Arbor Diameter 1". -- Saw Blade Size 8½" - 12". -- Throat to Blade Depth 15". -- Table Dimensions 33" x 59". -- 10 HP Main Motor. -- Spindle Speed 4,500 RPM. -- Feed Motor 1 HP. -- Feed Chain Width 6". -- Feeding Speed 30 - 85 RPM. -- Automatic Lubrication. -- Chip & Dust Collection Hood Diameter 4".Features: -- Cast iron and hard chrome plated table for durability & extended wear. -- Precision machined saw trunnion & fence assure optimal accuracy. -- Measuring ruler gauge for easy & accurate fence adjustments. -- Double anti-kickback fingers mounted at the infeed provide safety protection for the operator. -- Heavy-duty industrial motor for powerful cutting capacity. -- Rugged fabricated durable steel construction for years of use.Feed System: -- Variable speed settings enable the machine to meet different application needs. -- V-way track and chain block surfaces are heat-treated for longer, lasting usage. -- Automatic lubrication to V-Way track allows the chain to operate smoothly. -- (4) Pressure Rollers for accurate cutting of both large and small workpieces.Special Features: -- Saw arbor is manufactured from NI-Cr-MO alloy steel to provide the best durable and anti-fatigue, heat treated, and balanced for a more accurate cut. -- (4) Bearing spindle mount for prolonged life usage.

CAM-WOOD TRS-3020 Single Blade Bottom Cut Straight Line Rip SawEquipped with & Features: -- Precision fence ensures absolute accuracy between blade & fence, equipped with measuring ruler gauge. -- Double anti-kickback fingers mounted at the infeed end provides maximum safety protection. -- Heavy-duty industrial motor for powerful cutting capacity. -- Ruggedly constructed cast iron frames for durability usage. -- The variable feed speed enables the machine to meet different requirements of work. -- V-way track and chain block surface are heat-treated for long wear resistance. Automatic lubrication to the V-Way track facilitates the chain running smoothly. -- Precision-built saw head ensures accuracy for straight line rip saw operations. -- Four bearing spindle mount ensures rigidity & long life. -- Anti-kickback finger, two long rollers, in front of the saw blade, 4 x 2 = 8 short rollers at the side of the saw blade, two long rollers at outfeed. -- The auto lubrication device is equipped with an alarm that sends signals upon a lack of lubrication oil to increase the durability of the machines.Specifications -- Maximum Cutting Depth 5-5/8" -- Arbor Diameter 2" -- Max. Amount of Blades Per Spindle -- 1 Saw Blade Size 20" -- Table Dimensions 45" x 78" -- Spindle Speed 3600 RPM -- Feeding Speed 30 ~ 85 -- Throat to Blade Depth 26" -- Main Motor 20 HP -- Feed Motor 3 HP -- Feed Chain Width 8-3/4" -- Automatic Lubrication YES -- Minimum Workpiece Length 8" Exhaust -- Hood Diameter 1 4" x 1 + 5"; x 1 -- N.W. 4100 LBS

CAM-WOOD TRS-3018 Single Blade Bottom Cut Straight Line Rip SawEquipped with & Features: -- Precision fence ensures absolute accuracy between blade & fence, equipped with measuring ruler gauge. -- Double anti-kickback fingers mounted at the infeed end provides maximum safety protection. -- Heavy-duty industrial motor for powerful cutting capacity. -- Ruggedly constructed cast iron frames for durability usage. -- The variable feed speed enables the machine to meet different requirements of work. -- V-way track and chain block surface are heat-treated for long wear resistance. Automatic lubrication to the V-Way track facilitates the chain running smoothly. -- Precision-built saw head ensures accuracy for straight line rip saw operations. -- Four bearing spindle mount ensures rigidity & long life. -- Anti-kickback finger, two long rollers, in front of the saw blade, 4 x 2 = 8 short rollers at the side of the saw blade, two long rollers at outfeed. -- The auto lubrication device is equipped with an alarm that sends signals upon a lack of lubrication oil to increase the durability of the machines.Specifications: -- Maximum Cutting Depth: 4-3/4", Arbor Diameter 2". -- Saw Blade Size: 14" - 18" in diameter. -- Table Dimensions: 58" x 78". -- Spindle Speed: 3,600 RPM. -- Feeding Speed: 30 - 85 FPM. -- Throat to Blade 26". -- Main Motor: 20 HP, Feed 3 HP motor. -- Feed Chain Width: 8-3/4". -- Minimum Workpiece Length: 8" . -- Exhaust Hood Diameter 4". -- NW: 3,800 Lbs. Note: LA-6000 Laser Beam Light Available @ $980.00

CAM-WOOD TRS-1112 12" Single Blade Top Cut Straight Line Rip Saw;Precision machining and attention to operator safety and production needs, makes this saw one of the most cost effective Rip Saws available in the world today.Features: -- Hard chrome-plated table for maximum wear resistance. -- Precision fence ensures absolute accuracy between blade & fence, equipped with measuring ruler gauge. -- Double anti-kickback fingers mounted at the infeed end provides maximum safety protection. -- Heavy-duty industrial motor for powerful cutting performance. -- Ruggedly constructed sheet metal frame for durability usage. Feed & Saw Head: -- The variable feed speed enables the machine to meet different requirements of work. -- V-way track and chain block surface are heat-treated for long wear resistance; automatic lubrication to the V-Way track facilitates chain running smoothly. -- Precision-built saw head ensures accuracy for straight-line rip saw operations. -- The saw arbor is manufactured from NI-Cr-MO alloy steel for durability and anti-fatigue, heat treated, precision ground, and balanced providing precise cutting performance. -- Four-bearing spindle mount ensures rigidity & long life. Four pressure rollers for precise cutting of large and small workpieces. -- Heavy-duty cast iron table.Specifications: -- Max. cutting depth: 3-3/8". -- Arbor dia.: 1". -- Saw blade size: 12" diameter. -- Table dimensions: 28" X 61". -- Spindle speed: 3,300 RPM. -- Feed speed: 30 - 72 FPM; -- Throat to blade depth: 15". -- Main motor: 11.75 KW (15.75 HP) -- Feed motor: 1 HP. -- Feed chain width: 6". -- Automatic lubrication. -- Min. work piece length: 12". -- Exhaust Hood Dia. 4". -- Net weight: 1,960 Lbs.Options: -- AF-RT EXTENSION ROLLERS SIDE TABLE ...$390.00 • LA-6000 LASER BEAM LIGHT ...$980.00

CAM-WOOD TRS-2216 -- 16" Single Blade Bottom Cut Straight Line Rip Saw;Precision fence ensures absolute accuracy between blade & fence, with a precision gauge.Equipped with and Features: -- Double anti-kickback fingers mounted at the infeed end provides maximum safety protection. -- Heavy-duty industrial motor for powerful cutting capacity. -- Ruggedly constructed cast iron frames for durability usage. -- The variable feed speed enables the machine to suit different wood species and work applications. -- V-way track and chain block surface are heat-treated for long wear resistance. -- Automatic lubrication to V-Way track facilitates chain running smoothly. -- Precision built saw head ensures accuracy for straight line rip saw operations. -- Four bearing spindle mount ensures rigidity & long life. -- Anti-kick finger, two long rollers, in front of saw blade, 4 x 2 = 8 short rollers at side of saw blade, two long roller at out feed. -- The auto lubrication device is equipped with an alarm that sends signals upon a lack of lubrication oil. Specifications: -- Max. cutting depth: 3-1/8". -- Arbor dia.: 2". -- Saw blade size: 16". -- Spindle speed: 3,300 RPM. -- Feed speed 21 - 85 FPM. -- Throat to blade depth 16". -- Main motor: 10 HP. -- Feed motor 2 HP. -- Min. work piece length: 8". -- Dust Collection Hood dia. 4".Options- LA-6000 LASER BEAM LIGHT ...$980.00