Woodworking Equipment For Sale

1988 Results Found

$ 39,800

CAM-WOOD SM-155AX Feed Through Moulder 5-Head Moulder with a 6" width and a 4.75" max. thickness capacity.Overall Description: -- Cast Iron mainframe to maximize stability & minimize vibration during operation for years of use. -- Fully enclosed sound hood with lift-up door for easy set-up access. -- Adjustable infeed table w/fence for straightening rough sawn material. -- 16 - 66 FPM Variable feed speed system with top-driven rollers. -- All spindle adjustments except 1st bottom spindle with mechanical digital readouts. -- Left and Top spindles with mechanical Digi-set readouts. Chipbreaker and pressure element with mechanical digital readouts for accurate adjustment and precise settings.Complete with: 5' Infeed table length, Chromed table plates, fences, and pressure shoes. Manual Waxilit pump, Central lubrication of the machine from the front side.Specifications: -- Max. (Min.) Working Width 6" (3/4") -- Max. (Min.) Working Thickness 4-3/4" (5/16") -- Min. Working Length 9½". -- 1st Spindle Horsepower 7½ HP. -- 2nd, 3rd Spindle Horsepower 5½ HP, 5½ HP; -- 4th, 5th Spindle Horsepower 10 HP, 7½ HP. -- Cutterhead Dia.: 1st Bottom Head 5" dia.; 2nd, 3rd Vertical Head 5" - 6-1/4" dia.: 4th, 5th Head 5" - 7" diameter. -- Feed Motor 4 HP. -- Elevation 1 HP motor. -- Spindle Diameter 40 mm. -- Cutter Head Speeds 6,500 RPM. -- Variable Feed Speeds 16 ~ 66 FPM. -- Pneumatic Air 90 PSI (5 CFM by bolume) -- Dust Outlet Diameter 5" x 5" -- Net Weight 5,900 Lbs; Gross Weight 6,700 LbsIncludes: -- Operator/spare parts manuals and setup tools.

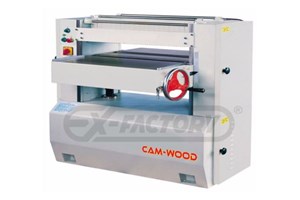

$ 10,990

CAM-WOOD WP-2400S SINGLE SIDED PLANER WITH SPIRAL HEADFeatures & Specifications: -- Self-braking motor 5 HP, Magnetic starter & thermal overload switch. -- Solid cast iron construction. -- Precision ground cast iron table w/manual adjustment by hand wheel via (2) large lead screws, up to 7" opening. -- Scale & pointer readout for accurate thickness adjustments. Spiral Head & Feed: -- Fixed feed speed setting for consistent stock removal. -- Sectional steel infeed roller & segmented chip breaker. -- Independently adjustable feed rollers. -- (2) Externally adjustable bed rollers.Complete with: -- Hinged top for easy access to cutterhead & gear assembly. -- Emergency stop. -- Operations manual, parts list & tool kit.1250 lbs

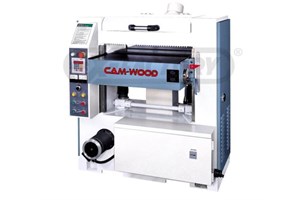

$ 39,990

CAM-WOOD WP-1010H 40"; Heavy Duty Planer with S.C.H.Features & Specifications: -- Precision ground cast iron table with motorized worktable raising & lowering manual adjustment by hand wheel via (2) large lead screws. -- Digital thickness display with touchpad positioning control for accurate thickness adjustments. -- Maximum thickness capacity 8" -- 5" Spiral cutterhead with 4-sided carbide inserts provide precise, efficient planing with low noise levels. -- With (4) each 4" diameter dust outlets -- 20 HP Main drive motor. -- 3 HP Variable feed speed 10 to 50 FPM. -- Maximum depth of cut 1/4". -- Sectional steel infeed roller & segmented chip breaker. -- Independently adjustable feed rollers. -- (2) Externally adjustable bed rollers. -- Hinged top for easy access to cutterhead & gear assembly. -- Self-braking motor. -- Magnetic starter & thermal overload switch. -- Emergency stop. -- Operations manual, parts list & tool kit. Machining Specifications: -- Max. Cut Width 40" -- Max. Cut Thickness 8" -- Max. Cut Depth ¼" -- Min. Cut Length 9" -- Cutting Speed 3600 RPM -- Table Size (W x L) 43" x 55" -- Main Motor 20 HP, 3 Ph -- Feed Motor 3 HP -- Table Raising Motor 1 HP -- Feed Rate (Variable) FPM 10 ~ 50 -- Net Weight 4,750 Lbs -- Shipping weight 5,500 LbsFOR UPGRADE TO 25 HP ADD ...$900.00

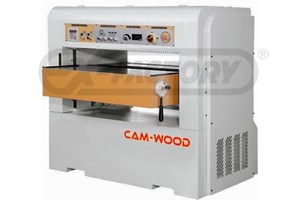

$ 18,990

CAM-WOOD WP-660A Single-Sided 15 HP, 26" PlanerFeatures: -- Spiral cutter-head with inserts provide precise, efficient planing with low noise levels. -- Automatic digital thickness controller for quick & accurate settings. -- The motorized worktable raises & lowers by a separate motor for more efficient operation. -- The specially designed infinitely variable feed system is powered by a separate motor and allows adjustment to the optimal feed rate for planing a precision smooth finish on both hard and softwoods. -- The sectional infeed roller & anti-kickback device & chip breaker provide greater safety for the operator -- Exhaust dust hood with 4"; dia. outlet for proper chip extraction. -- The motorized worktable includes quick adjustable twin bed rollers for rough & finish planning on damp or dry lumber ensuring a consistently smooth planed finish. -- Precision-sealed long-life ball bearing. -- Industrial motor for powerful cutting capacity. Heavy gauge sheet metal frame and base.Specifications: -- Table Area 35" x 27". -- Max. Planing Width 26". -- Max. Planing Thickness 11-3/4" -- Mini. Planing Thickness 3/16" -- Cutterhead Speed 5,500 RPM. -- Cutterhead Diameter 4-3/4" Spiral. -- Knife Dimensions 14 mm x 14 mm. -- Feeding Speed (Var.) 15 - 60 FPM. -- Max. Cutting Depth 3/8". -- Feed Motor 1 HP. -- Cutterhead Motor 15 HP, 3 Ph, 230 V. -- Table Elevation Motor 1 HP. -- Digital Thickness Control. -- Dust Hood Outlet 5".

$ 7,990

CAM-WOOD WP-2400 Single Sided PlanerFeatures & Specifications: -- Solid cast iron construction. -- Precision ground cast iron table w/manual adjustment by hand wheel via (2) large lead screws. -- Scale & pointer readout for accurate thickness adjustments. -- solid steel 3 knife cutter head -- Fixed feed speed setting for consistent stock removal. -- Sectional steel infeed roller & segmented chip breaker. -- Independently adjustable feed rollers. -- (2) Externally adjustable bed rollers. -- Hinged top for easy access to cutterhead & gear assembly. -- Self-braking motor 5 HP. -- Magnetic starter & thermal overload switch. -- Emergency stop. -- Operations manual, parts list & tool kit..

$ 13,690

CAM-WOOD WP-610A Single-Sided Planer 10 HP - 24" Cap. Features: -- 24" Spiral cutter head provides precise, efficient planing with low noise levels. -- Automatic digital thickness controller for quick & accurate setting. -- Motorized worktable raises & lowers by separate motor for more efficient operation. -- Specially designed infinitely variable feed system is powered by a separate motor and allows adjustment to the optimal feed rate for planing to a precise smooth finish on both hard or softwoods. -- The sectional infeed roller & anti-kickback device & chip breaker gives the operator greater safety. -- Up to 8"; thickness large cutting capacity. -- Exhaust dust hood with 4"; dia. outlet for proper chip extraction. -- The motorized worktable includes twin quick adjustable bed rollers that can be adjusted for rough & finish planing on damp or dry lumber ensuring a consistently smooth planed finish. -- Precision sealed long-life ball bearing. -- Industrial motor for powerful cutting capacity. Heavy gauge sheet metal frame and base for maintenance-free service.Specifications: -- Table area 25" x 28". -- Max. planing width 24". -- Feed Speed (Var.) 15 ~ 60 FPM. -- Max thickness 8'' and min. Planing Thickness 1/8". -- Elevation Motor 0.5 HP. -- Cutterhead Speed 5,500 RPM. -- Cutter head diameter 4-3/4", Spiral. -- Knife insert dimensions 14 mm x 14 mm. -- Max. Cutting Depth 5/16";. -- Feed Motor 1 HP. -- Cutterhead Motor 10 HP. -- G.W. 1,850 LBS / 2,000 Lbs.

$ 20,990

CAM-WOOD WP-760 15 HP Single Sided 30" Planer Features: -- Spiral cutterhead provides precise, efficient planing with low noise levels. -- Automatic digital thickness controller for quick & accurate setting. -- Motorized worktable raises & lowers by separate motor for more efficient operation. -- Specially designed infinitely variable feed system is powered by a separate motor and allows adjustment to the exact feed rate and allows precision smooth finish planing on both hard or softwoods. -- The sectional infeed roller & anti-kickback device & chip breaker provides greater safety for the operator -- Exhaust dust hood with 4"; dia. outlet for proper chip extraction. -- The motorized worktable includes twin quick adjustable bed rollers that can be adjusted for rough & finish planing on damp or dry lumber ensuring a consistently smooth planed finish. -- Precision sealed long-life ball bearing. -- Industrial motor for powerful cutting capacity. Heavy gauge sheet metal frame and base for maintenance-free serviceSpecifications: -- Table Area 38" x 31" -- Max. Planing Width 30" -- Max. Planing Thickness 8" -- Mini. Planing Thickness 3/16" -- Cutterhead Speed 5,500 RPM -- Cutterhead Diameter 4-3/4" Spiral -- Knife Dimensions 14 mm x 14 mm -- Feeding Speed (Var.) 15 ~ 75 FPM -- Max. Cutting Depth 5/16" -- Feed Motor 2 HP -- Cutterhead Motor 15 HP, 3 Ph, 230 V -- Table Elevation Motor 1 HP -- Digital Thickness Control Yes -- Dust Hood Outlet 5"G.W. 2450 Lbs

$ 8,389

CAM-WOOD WP-2000S Single Sided Planer20" Planer with solid cast iron construction and Spiral Cutter Head.Features & Specifications: -- Precision ground cast iron table w/manual adjustment by hand wheel via (2) large lead screws. -- Scale & pointer readout for accurate thickness adjustments. -- Fixed feed (30 FPM) speed setting for consistent stock removal. -- Sectional steel infeed roller & segmented chip breaker. -- Independently adjustable feed rollers. -- (2) Externally adjustable bed rollers. -- Hinged top for easy access to cutterhead & gear assembly. -- 3 HP Self-braking motor. -- Magnetic starter & thermal overload switch and Emergency stop. -- Operations manual, parts list & tool kit. Optional: CT-SCH-14T - 14 mm x 14 mm SPIRAL CUTTERHEAD BLADES ...$3.30 each

CAM-WOOD TRS 0012, Straight Line Rip-SawSpecifications: -- Max. cutting depth 3-3/4". -- Arbor Diameter 1". -- Saw Blade Size 8½" - 12". -- Throat to Blade Depth 15". -- Table Dimensions 33" x 59". -- 10 HP Main Motor. -- Spindle Speed 4,500 RPM. -- Feed Motor 1 HP. -- Feed Chain Width 6". -- Feeding Speed 30 - 85 RPM. -- Automatic Lubrication. -- Chip & Dust Collection Hood Diameter 4".Features: -- Cast iron and hard chrome plated table for durability & extended wear. -- Precision machined saw trunnion & fence assure optimal accuracy. -- Measuring ruler gauge for easy & accurate fence adjustments. -- Double anti-kickback fingers mounted at the infeed provide safety protection for the operator. -- Heavy-duty industrial motor for powerful cutting capacity. -- Rugged fabricated durable steel construction for years of use.Feed System: -- Variable speed settings enable the machine to meet different application needs. -- V-way track and chain block surfaces are heat-treated for longer, lasting usage. -- Automatic lubrication to V-Way track allows the chain to operate smoothly. -- (4) Pressure Rollers for accurate cutting of both large and small workpieces.Special Features: -- Saw arbor is manufactured from NI-Cr-MO alloy steel to provide the best durable and anti-fatigue, heat treated, and balanced for a more accurate cut. -- (4) Bearing spindle mount for prolonged life usage.

$ 45,900

CAM-WOOD 102PAAU Raised Panel Door MachineMachines entry door stile and rail door parts as well as cabinet door parts, chair legs and furniture parts, up to 102" in length and 7" in width. One operator to machine profiles for the rail copes, stile and rail sticking and raised panels with rapid changeover, all on one machine with high productivity. Features Include: -- Hydraulic table movement from right to left to achieve powerful cutting and adjust cutting speed variability. Table movements in and out are pneumatically powered following a template with very high accuracy. -- One operator to machine all profiles for stiles and rails on one machine, along with raising all panels both edges top and bottom. -- Capacity for machining a 6" arch/oval on panels and rails, and raising both faces on a raised panel at the same time (arc size varies depending on cutter diameter). -- Raise a curved panel up to 6" radius both on rails and panels. -- Machines door stiles up to 102" in length.Technical Features: -- Hydraulic pump unit for accurate table speed control. -- Simple guide system follows templates for curved or arched profiles and is quickly repositioned for straight machining profiles. -- Cutterhead knives can be stacked on the same spindle to eliminate changing machines to machine door parts. -- Easy stop system for door stiles or rail lengths. Two separate stops work for rail/stile/panel arch cut positions. -- Heavy duty 15 HP motor, allows for high speed cutterhead to eliminate unnecessary sanding. -- Proximity switches control the cutting stroke. Linear guide rails and bearing for a lightweight & smooth slide. -- More than one part may be milled at one time. Pneumatic holddown cylinders hold parts tightly without slide during cutting. -- Easy positioning of parts on a precision ground, cast iron table ensures accurate stile rail and panel machining and alignments.More Specifications: -- Spindle Motor 15 HP @ 7,000 RPM; Hydraulic Motor 1 HP; Feed Speed 0-60 FPM. -- Spindle Diameter 1-1/4"; Spindle Height 7"; -- Depth of Radius Cut 6";; Min. Radius Cut 6" (based on cutter diameter). Dust Hood is 4" dia. Dimension: -- Machine Length 120";; Operating Length 228";; Width 48";; Height 48";, Weight 300 Lbs; Air Supply Required 100 PSINote: Delivery time about 10-12 weeks.

$ 35,500

CAM-WOOD "PROFORMA" CNC Routers w/ATC for "Nested Base Manufacturing" including Cabinets, Three-Dimensional Wood Processing, Wooden Doors, Furniture & Window Processing; as well as Plastic Processing and Engraving.SERIES 404: $ 35,500SERIES 408: $ 37,720SERIES 510: $ 39,940Models Include (Table Sizes): 404 (4' x 4'), 408 (4' x 8'), 510 (5' x 10')General Specs: Machine Gantry X Axis Square Rails Parallel Vertical Accuracy 0.001"; (0.03mm), Y Axis Square Rails Parallel Vertical Accuracy 0.001"; (0.03mm), Z Axis Ball Screw Parallel Vertical Accuracy 0.001"; (0.03mm), Re-Position Accuracy 0.001"; (0.02mm), Working Accuracy 0.004"; (0.10mm), Grating Ruler Travel Accuracy 0.002"; (0.05mm).Control System: WEIHONG NK105 G3Spindle: 9.0kW (12 Hp) Air-Cooled Spindle 6,000 - 24,000 RPMBed Frame: Heavy-Duty Metal WeldingTable: (6) Zone Vacuum TableDriving System: Servo-Motor and DriverY Axis Driving System: Helical Rack & PinionX & Z Axis Driving System: HIWIN Ball-screw Axis Square Rail: HIWIN Linear Square RailATC: SERIES 404: Rear Linear (6) Tools ISO30, ER32 - SERIES 408/510: Rear Linear (8) Tools ISO30, ER32Inverter: SCHNEIDER 11 kWLimit Switch: OMRONElectrical Wiring: SIEMENSControl Switch: MOELLERWorking Size:SERIES 404: 51’’ (X) x 51’’ (Y) x 7-3/4’’ (Z)SERIES 408: 51’’ (X) x 98’’ (Y) x 7-3/4’’ (Z)SERIES 510: 63’’ (X) x 126’’ (Y) x 7-3/4’’ (Z)Machine Size (L x W x H):SERIES 404: 87’’ (X) x 74’’ (Y) x 71’’ (Z)SERIES 408: 87’’ (X) x 122’’ (Y) x 71’’ (Z)SERIES 510: 99’’ (X) x 149’’ (Y) x 71’’ (Z)Max Travel Speed: 2350 IPMMax Working Speed: 1100 IPMMachine Net Weight: SERIES 404: 3,520 lbs / SERIES 408: 3,960 lbs / SERIES 510: 4,480 lbsFeatures Include: -- Automatic (12) Tools Linear Type Auto Tool Changer Under the Bridge for Increased Productivity. -- All “Servo Motor"; Driving System: All Axes are Driven by Brush-less Type, High Torque AC Servo Motors. -- DSP CNC Controller is Setup to Accept Standard G-Code Programming Formats Along with On-Board Conversational Applications. -- Optional CAD/CAM System can Create and Edit Part Programs Then Send to Machine for Easy Cutting. DXF Files can be Imported, Modified, and Edited from Here to Create a G-Code. -- DNC is No Longer Required as the PC Directly Stores all Part Programs in a Text Editable File. -- Machine Designed Ready for 3-D Cutting Usage and Superior Performance. -- Moving Gantry Construction for Space Saving. -- The Rigid Steel Frame Construction has been Stress-Relieved Prior to Finish Machining to Provide Repeatability and Accuracy. -- Automatic Frequency Brake for the Spindle Allows Rapid Deceleration Resulting in Faster Tool Changes. -- Linear Guides and Sliding Blocks are Pre-loaded with Recirculation Bearings to Ensure Maximum Rapid Traverse and Precision. --Th

CAM-WOOD CC-388PA Clamp Carrier (8 Sections)8-Section Pneumatic Clamp Carrier with 98" length capacity.Equipped with: -- (6) Heavy Duty zinc plated clamps per section (48 clamps total). -- 40" Opening on clamps. -- Jaw sizes of clamps are 3-1/2" with inward draft. -- Pneumatic overhead panel flattener. -- Pneumatic clamp tightener and 1/2 HP electric motor rotation.Standard features: -- Large I-beam frame & legs for max. rigidity and durability. -- Heavy-duty zinc-plated clamp with huge 3/4" diameter jack bolt for super strength. -- Powerful caterpillar chain drive for clamp rotation. -- Select switch control for auto or manual mode.Includes: -- Clamp tightener with pneumatic wrench for rapid tightening and loosening of clamp. -- Pneumatic panel flattener to hold panels flat while clamps are tightened.Versatile and reliable Edge Gluing Machine for Solid Wood gluing, including laminate board, parquet, flat stock, table top, core block, truck flooring, turnings, chair seat, legs, spindle blanks, stair tread, and many others.

$ 60,000

CAM-WOOD "DYNAMIC" CNC Routers w/ATC for "Nested Base Manufacturing" including Cabinets, Three-Dimensional Wood Processing, Wooden Doors, Furniture & Window Processing; as well as Plastic Processing and Engraving.SERIES 408: $ 60,090SERIES 510: $ 63,800SERIES 512: $ 65,080Models Include (Table Sizes): 408 (4' x 8'), 510 (5' x 10'), 510 (5' x 12')General Specs: Machine Gantry X Axis Square Rails Parallel Vertical Accuracy 0.001"; (0.03mm), Y Axis Square Rails Parallel Vertical Accuracy 0.001"; (0.03mm), Z Axis Ball Screw Parallel Vertical Accuracy 0.001"; (0.03mm), Re-Position Accuracy 0.001"; (0.02mm), Working Accuracy 0.004"; (0.10mm), Grating Ruler Travel Accuracy 0.002"; (0.05mm).Control System: SYNTEC Control SystemSpindle: 9.0kW (12.8Hp) HSD Air-Cooled Spindle - 6,000 - 24,000 rpmBed Frame: Heavy-Duty Metal WeldingTable: (6) Zone Vacuum TableDriving System: YASKAWA Servo Drive and MotorY Axis Driving System: Helical Rack & PinionX & Z Axis Driving System: HIWIN Ball-screw Axis Square Rail: HIWIN Linear Square RailATC: Rotary (12) Tools ISO30, ER32Inverter: 11 kWLimit Switch: OMRONElectrical Wiring: SIEMENSControl Switch: MOELLERTool Length Device: AutomaticVacuum Pump: OptionalDrill Bank: Includes (9) Tools HSDCAD/CAM Software: OptionalWorking Size:SERIES 408: 51’’ (X) x 98’’ (Y) x 7-3/4’’ (Z)SERIES 510: 63’’ (X) x 126’’ (Y) x 7-3/4’’ (Z)SERIES 512: 63’’ (X) x 150’’ (Y) x 7-3/4’’ (Z)Machine Size (L x W x H):SERIES 408: 87’’ (X) x 122’’ (Y) x 71’’ (Z)SERIES 510: 99’’ (X) x 149’’ (Y) x 71’’ (Z)SERIES 512: 99’’ (X) x 173’’ (Y) x 71’’ (Z)Max Travel Speed: 2 350 IPMMax Working Speed: 1 100 IPMMachine Net Weight: SERIES 408: 3,960 lbs / SERIES 510: 4,480 lbs / SERIES 512: 4,970 lbsFeatures Include: --Automatic (12) Tool Rotary Type Auto-Tool Changer for Increased Productivity. --All “Servo Motor"; Driving System: All Axes are Driven by Brush-Less Type, High Torque AC Servo Motors. --DSP CNC Controller is Setup to Accept Standard G-Code Programming Formats along with On-Board Conversational Applications. --Optional CAD/CAM System can Create and Edit Part Programs then Send to Machine for Easy Cutting. DXF Files can be Imported, Modified and Edited from here to Create a G-Code. --DNC is no Longer Required as the PC Directly Stores all Part Programs in a Text Editable File. --Machine Designed Ready for 3-D Cutting Usage and Superior Performance. --Moving Gantry Construction for Space Saving. --The Rigid Steel Frame Construction has been Stress-Relieved Prior to Finish Machining to Provide Repeatability and Accuracy. --Automatic Frequency Brake for the Spindle Allows Rapid Deceleration Resulting in Faster Tool Changes. --Linear Guides and Sliding Blocks are Pre-Loaded with Recirculation Bearings to Ensure Maximum Rapid Trav

CAM-WOOD "PROFORMA LN" CNC Routers w/ATC for "Nested Base Manufacturing" including Cabinets, Three-Dimensional Wood Processing, Wooden Doors, Furniture & Window Processing; as well as Plastic Processing and Engraving.SERIES 408 LN: $ 43,300SERIES 510 LN : $ 46,600Models Include (Table Sizes): 408 LN (4' x 8'), 510 LN (5' x 10')General Specs: Machine Gantry X Axis Square Rails Parallel Vertical Accuracy 0.001"; (0.03mm), Y Axis Square Rails Parallel Vertical Accuracy 0.001"; (0.03mm), Z Axis Ball Screw Parallel Vertical Accuracy 0.001"; (0.03mm), Re-Position Accuracy 0.001"; (0.02mm), Working Accuracy 0.004"; (0.10mm), Grating Ruler Travel Accuracy 0.002"; (0.05mm).Control System: SYNTEC Control SystemSpindle: 9.0kW (12 Hp) Air-Cooled Spindle 6,000 - 24,000 RPMBed Frame: Heavy-Duty Metal WeldingTable: (6) Zone Vacuum TableDriving System: Lead-Shine Servo Drive and MotorY Axis Driving System: Helical Rack & PinionX & Z Axis Driving System: HIWIN Ball-screw Axis Square Rail: HIWIN Linear Square RailATC: SERIES Linear (12) Tools ISO30, ER32Inverter: SCHNEIDER 11 kWLimit Switch: OMRONElectrical Wiring: SIEMENSControl Switch: MOELLERTool Length Device: AutomaticVacuum Pump: OptionDrill Bank: Optional (9) Tool HSDCAD/CAM Software: OptionWorking Size:SERIES 408 LN: 51’’ (X) x 98’’ (Y) x 7-3/4’’ (Z)SERIES 510 LN: 63’’ (X) x 126’’ (Y) x 7-3/4’’ (Z)Machine Size (L x W x H):SERIES 408 LN: 122’’ (X) x 87’’ (Y) x 71’’ (Z)SERIES 510 LN: 99’’ (X) x 149’’ (Y) x 71 (Z)Max Travel Speed: 2 350 IPMMax Working Speed: 1 100 IPMMachine Net Weight: SERIES 408 LN: 3,960 lbs / SERIES 510 LN: 4,480 lbsFeatures Include: --Automatic (12) Tools Linear Type Auto Tool Changer under the Bridge for Increased Productivity. --All “Servo Motor"; Driving System: All Axes are Driven by a Brushless Type, High Torque AC Servo Motors. --DSP CNC Controller is Setup to Accept Standard G-Code Programming Formats along with On-Board Conversational Applications. --Optional CAD/CAM System can Create and Edit Part Programs then Send to Machine for Easy Cutting. DXF Files can be Imported, Modified and Edited from Here to Create a G-Code. --DNC is no longer Required as the PC Directly Stores all Part Programs in a Text Editable File. --Machine Designed Ready for 3-D Cutting Usage and Superior Performance. --Moving Gantry Construction for Space Saving. --The Rigid Steel Frame Construction has been Stress Relieved Prior to Finish Machining to Provide Repeatability and Accuracy. --Automatic Frequency Brake for the Spindle Allows Rapid Deceleration Resulting in Faster Tool Changes. --Linear Guides and Sliding Blocks are Pre-Loaded with Recirculation Bearings to Ensure Maximum Rapid Traverse and Precision. --The X & Y Axis are Equipped with a Precision Rack & Pinion Driving System. The Z Axis Utilizes a Ball Screw Assembly Complete with the Pre-Loaded and

$ 35,990

CAM-WOOD WS-M1000 NAX Planer Sander -- 2 Heads with 39.4" width capacity planer head and combination sanding headFeatures: -- This machine is especially designed for tale off heavy materials such as glue panel, bend board, rough lumber. -- The first head is a knife planer head, with 25 HP motor. The spiral planer cutterhead is fitted with 14 x 14 mm, four edge throw away Tungsten Carbide knife inserts, providing superior chip removal rate, minimum noise, and extremely smooth cutting effect. Changing knife inserts are conveniently done without removing the cutterhead. -- The second head is a combination of drum and platen driven by a 20 HP motor, belt size 40.5" x 78 3/4". (1030mm X 2000 mm) -- Anti-kickback fingers, mounted at the infeed of the machine, this anti-kickback finger gives a safety guard for the operator. -- Insufficient pressure protection, in case insufficient working air pressure occurs, the machine brakes automatically for safety guard.Irreversible running of pressure roller, runs a single direction only, giving an additional safety guard for panel kickback. -- Motorized elevation of conveyor table (micro-computer controlled with digital readout), it accurately displays the position of the conveyor table and automatically moves to the setting thickness for planning, sanding. -- Panel cleaning brush roller; built at outfeed end of the machine, this cleaning brush roller cleans the powder on the sanded panel. -- Hold-down plate is hard chrome treated for maximum wear resistance.Technical Specification: -- Working width 39.4" (1000 mm). -- Working thickness up to 6 1/4". -- Minimum working length 21". -- Feed speed 10 to 90 FPM inverted driven by 3 HP motor. -- Table raised and lowered by 1/2 HP motor. -- Cleaning brush driven by 1/2 HP

CAM-WOOD BR-2132 Boring Machine21-Spindle boring head on 32 mm centers with position indicator.Features & Specifications: -- Stops in 0° & 90° with pneumatically assisted positioning in vertical & horizontal. -- 0" - 3" Adjustable drilling depth with speed control. -- Head height fine adjustment with mechanical digital readout. -- 2 HP - 3,400 RPM Motor. -- Cast iron 37-1/2" x 19-1/4" table with side fences for mirror-image. -- Line boring fence with repeat stops. -- Foot actuated pneumatic clamps & drill cycle.Complete with: Magnetic starter, overload protection. -- Optional: Quick-change chucks $28.00 ea.

CAM-WOOD BR-2732X Boring Machine32-Spindle boring head on 32 mm centers with position indicator.Features & Specifications: -- Stops in 0° & 90° with pneumatically assisted positioning in vertical & horizontal. -- 0" - 3" Adjustable drilling depth with speed control. -- Head height fine adjustment with mechanical digital readout. -- (2) 2 HP - 3,400 RPM Motors. -- Cast iron 45" x 31-1/2" table with side fences for mirror-image. -- Line boring fence with repeat stops. -- Foot actuated pneumatic clamps & drill cycle.Complete with: -- Magnetic starter, overload protection. -- Optional quick-change chucks $28.00 ea.

CAM-WOOD BR-3532X CONSTRUCTION BORING MACHINE35-Spindle boring head on 32 mm centers with position indicator.Features & Specifications: -- Stops in 0° & 90° with pneumatically assisted positioning in vertical & horizontal. -- 0" - 3" Adjustable drilling depth with speed control. -- Head height fine adjustment with mechanical digital readout. -- (2) 2 HP - 3,400 RPM Motors. -- Cast iron 52" x 19-1/4" table with side fences for mirror-image. -- Line boring fence with repeat stops. -- Foot actuated pneumatic clamps & drill cycle.Complete with: -- Magnetic starter, overload protection. -- Optional quick-change chucks $28.00 ea.

CAM-WOOD BR-50 Universal Boring MachineFeatures & Specifications: -- 3 HP Pneumatic Universal Boring Machine, all adjustments feature an index plate for accurate and convenient reading, workplace clamping. -- Vertical Base travel, 24". Horizontal Base travel 12". -- 0" - 4" Spindle stroke, 7/16" - 14-thread screw shank, 1/2" max. bit capacity. -- Table Size: 15" x 22". -- Complete with: Air operated overhead holddown clamp and foot pedal operated drill cycle. -- Drill Head can be swiveled 360° and Optional Multi-Spindle drill heads available.

CAM-WOOD BR 25 Horizontal DrillFeatures & Specifications: -- Single Spindle, 2 HP - 3450 RPM 3-phase motor, adjustable vertically and front to back. -- 5" Horizontal spindle travel (drilling depth) w/foot pedal control. -- 3-1/2" Vertical table adjustment. -- Pneumatic holddown clamp for up to 3" thickness. -- 12" x 10" Table size. -- 1/2" Drill chuck / 3/4" max. bit diameter.

.gif)