704-841-2001

Backed with a massive machinery database considered to be “the blue book” of woodworking machinery), EX-FACTORY Auctions provides a complete assessment of your equipment and allows you to interact with the market real-time in our dynamic Online Auction!

2029 Results Found

704-841-2001

Call for Price

BRANDT AMBITION 1440 (KDF-440 C) EDGEBANDER (W/PRE-MILL & CORNER ROUNDING): -- Specifications: Edge & workpiece capacity: 0.4 - 8 mm (0.016" - 0.31") Edgebanding thickness, 8 - 60 mm (0.31" - 2.36") panel thickness, 160 mm (6.30") min. panel length, 70 mm (2.76") min. panel width.Equipped with: -- Adjustable Infeed Fence: Manual adjustment. -- Joint Trimming/Pre-milling Station: (2) 2.2 kW (3 HP) 12,000 RPM Motors, left-hand & right-hand rotation with Pneumatic jump control for chip-free & clean panel edges. -- Roller Separating Device: 3 mm x 45 mm (0.12" x 1.77") or 1 mm x 55 mm (0.04" x 2.17") Max. roll cutting; 0.4 - 8 mm (0.016" - 0.31") strip thickness; 3 mm (0.12") PVC max. coil thickness. -- Hot Melt Glue Application Unit: 6 - 10 kG/Hr (13 - 22 Lbs/Hr) Melting capacity (depending on glue type). -- Pressure Zone: (1) Driven & (2) idle rollers; timed pneumatic pressure controlled; Servo motor positioning for programmable edge thickness changeover. -- Feed Speeds: 8 - 14 MPM (27 - 45 FPM); 11 MPM (36 FPM) when contour trimming. -- BRANDT "POWERTOUCH" Control with: 21" HD LCD Touch Screen Monitor.Workstations: -- Front & Rear End Trimming Unit: (2) 0.18 kW (1/4 HP) 12,000 RPM Motors with 0° - 15° automatic chamfer, pneumatic adjustment & activation/deactivation of edging material overhang using "POWERTOUCH" control. -- Top & Bottom Flush/Chamfer/Radius Trimming Unit: (2) 0.55 kW (3/4 HP) 12,000 RPM Motors, 0° - 25° Automatic tilt with Horizontal & Vertical Tracing wheels, Brushless multi-axis Servo motors for positioning of work unit & horizontal copy wheels for quick changeover with (3) Positioning options: Profile 1, Profile 2 & Flush Trimming. -- Multifunctional Trimming Unit: (2) 0.4 kW (1/2 HP) - 12,000 RPM Motors for leading & trailing edges vertical corner rounding of panels, Servo motors for positioning of work unit & horizontal copy wheels. Either radius or chamfer cutters can be mounted, 3 mm (0.12") max. edge thickness. -- Top & Bottom Multi-Profile (PVC) Scraping Unit: (2) Profiles: 1 mm (0.04") & 2 mm (0.08") or 3 mm (0.12") instead of 2 mm (0.08"); Servo control positioning of vertical & horizontal copy wheels; PVC scrape collection box, pneumatic adjustment using "POWERTOUCH" control, pneumatic disengagement. -- Top & Bottom Glue Scraping Unit: Flush on panel surface with floating insert knives. -- Top & Bottom Buffing Unit: (2) 0.09 kW (0.12 HP) - 2,750 RPM Motors.Complete with: -- Rubber padded feed chain w/top idle hold-down rollers; 1.5 kW (2 HP) feed motor; 32" diameter coil table; padded sound enclosure. -- Actual Model is BRANDT AMBITION 1440 (KDF 440 C).

$23,750

BRANDT - KDF-550 C, ...Edgebander with Premill & Corner RoundingEdge & workpiece capacity. Edge: 0.4 - 8 mm (0.016 - 0.31"); panel thickness: 8 -60 mm (0.31" - 2-3/8"); min. panel length: 60 mm (6.29"); min. panel width: 70 mm (2-3/4").Equipped with: -- Premilling Station with: Diamond cutterheads; (2) motors @ 2.25 kW (3.0 HP) - 12.000 RPM; LH & RH rotation w/pneumatic jump control for chip free & clean panel edges. -- Infeed fence with: Servo motor positioning. -- Automatic Edge Magazine. For strip & coil stock; strips: 0.4 mm - 8 mm (0.016" - 0.31"); coils up to 3 mm PVC and "HD" guillotine. -- Pressure Section. 1st Roller driven; plus (3) idle rollers; timed pneumatic pressure controlled; Servo motor positioning for programmable edge thickness changeover. -- Feed Speed: Variable; 8 - 14 MPM (26 - 46 FPM); 11 MPM (36 FPM) when using contour trimming. -- BRANDT "PowerControl PC 16"; memory: 256 MB RAM; 1 GB Flash Card Drive; Operator control panel with: 22" Color HD wide screen; soft keypad; internal modem for remote diagnostic link.Workstations -- End Trimming; (2) Motors @ 0.35 kW (1/2 HP) 12,000 RPM; automatic chamfer from the control panel: 0°- 15°. -- Flush/Bevel-Fine/Radius Trimming Unit: Top/bottom (2) motors; 0.55 kW (3/4 HP) 12,000 RPM; auto tilt positioning 0° - 25°; combination flush/radius/chamfer cutterheads; horizontal and vertical tracing wheels. -- Includes: (3) Positioning options: Profile 1, profile 2, and flush trimming. -- Corner Rounding Unit: (1) Motor; 0.35 kW (1/2 HP) - 12,000 RPM for leading & trailing edges; vertical corner rounding of panels; either radius or chamfer cutters can be mounted; 3 mm max. edge thickness. -- Scraping, Multi-Profile (PVC) Top/Bottom with (2) profiles: 1 mm & 2 mm or 3 mm Instead of 2 mm; Servo control positioning of vertical & horizontal copy wheels; PVC scrape collection box. -- Scraping Glue Unit: Flush top/bottom on the panel surface with floating insert knives. -- Buffing Unit: Top/bottom (2) motors; 0.10 kW (0.125 HP) - 2,800 RPM.Complete with: Motorized, programmable holddown pressure beam; padded sound enclosure. -- Actual Model: BRANDT, OPTIMATKDF 550 C

BRANDT AMBITION 1440 FC (KDF-440 FC) EDGEBANDER (W/PRE-MILL & CORNER ROUNDING): -- SpecificationsEdge & workpiece capacity: 0.4 - 8 mm (0.016" - 0.31") Edgebanding thickness; 8 - 60 mm (0.31" - 2.36") panel thickness; 160 mm (6.30") min. panel length; 70 mm (2.76") min. panel width.Equipped with: -- Heated Adjustable Infeed Fence: Radiant heated with manual adjustment. -- Joint Trimming/Premilling Station: (2) 2.2 kW (3 HP) - 12,000 RPM Motors; left-hand & right-hand rotation with Pneumatic jump control for chip-free & clean panel edges. -- Roller Separating Device: 3 mm x 45 mm (0.12" x 1.77") or 1 mm x 55 mm (0.04" x 2.17") Max. roll cutting; 0.4 - 8 mm (0.016" - 0.31") strip thickness; 3 mm (0.12") PVC max. coil thickness. -- Hot Melt Glue Application Unit: 6 - 10 kG/Hr (13 - 22 Lbs/Hr) Melting capacity (depending on glue type). -- Pressure Zone: (1) Driven & (2) idle rollers; timed pneumatic pressure controlled; Servo motor positioning for programmable edge thickness changeover. -- Feed Speeds: 8 - 14 MPM (27 - 45 FPM); 11 MPM (36 FPM) when contour trimming. -- BRANDT "POWERTOUCH" Control with: 21" HD LCD Touchscreen Monitor.Workstations -- Front & Rear End Trimming Unit: (2) 0.18 kW (1/4 HP) 12,000 RPM Motors with: 0° - 15° Automatic chamfer, pneumatic adjustment & activation/deactivation of edging material overhang using "POWERTOUCH" control. -- Top & Bottom Flush/Chamfer/Radius Trimming Unit: (2) 0.55 kW (3/4 HP) 12,000 RPM Motors; 0° - 25° automatic tilt with Horizontal & Vertical Tracing wheels; Brushless multi-axis Servo motors for positioning of work unit & horizontal copy wheels for quick changeover with: (3) Positioning options: Profile 1, Profile 2 & Flush Trimming. -- Multifunctional Trimming Unit: (2) 0.4 kW (1/2 HP) - 12,000 RPM Motors for Top & Bottom, Leading & Trailing edges & Corner Rounding of panels, Servo motors for positioning of work unit & horizontal copy wheels. - Either radius or chamfer cutters can be mounted: 3 mm (0.12") Max. edge thickness. -- Top & Bottom Multi-Profile (PVC) Scraping Unit: (2) Profiles: 1 mm (0.04") & 2 mm (0.08") or 3 mm (0.12") Instead of 2 mm (0.08"); Servo control positioning of vertical & horizontal copy wheels; PVC scrape collection box; pneumatic adjustment using "POWERTOUCH" control; pneumatic disengagement. -- Top & Bottom Buffing Unit: (2) 0.09 kW (0.12 HP) - 2,750 RPM Motors.Complete with: -- Rubber padded feed chain w/top idle holddown rollers; 1.5 kW (2 HP) feed motor; 32" diameter coil table; padded sound enclosure. -- Actual Model BRANDT AMBITION 1440 FC (KDF 440 FC)

Call for Price

BRANDT PROFILINE KDF 970 2C HD EDGEBANDER WITH PRE MILL & CORNER ROUNDINGSpecifications: -- Edgebanding thickness 0.4 - 20 mm (0.02" - 0.79"), Including 3 mm (0.12") PVC banding. -- Panel thickness 8 - 60 mm (0.31" - 2.38"), Min. panel width 65 mm (2.56"), Min. panel length 160 mm (6.30"). -- Variable feed speeds 36 - 65 FPM (11 - 20 MPM), Max. feed speed using corner rounding units or applying solid wood 52 FPM (16 MPM). -- Working height 900 mm (35.43").Equipped with: -- Pre-milling unit, with (2) 3 kW (4 HP) - 11,580 RPM Vertical milling/jointing heads with FS Whisper Heads, Electro-pneumatic jump control, Head counter-rotation, & SIKO digital units for vertical & horizontal adjustments. -- 32-1/2" Dia. Coil table. -- Motorized infeed fence. -- Extended magazine for strips & coiled material. -- Reinforced guillotine for coiled edgebanding material, 0.4 - 3.5 mm (0.2" - 0.14") Thickness & 8 - 55 mm (0.31" - 2.17") Height. -- "Quick-Melt" Hot melt glue unit, with Heat-up time: Approx. 12 min., Pre-melt hopper feed, Quick-change hopper & tank for color changes, Reversible glue applicator roller rotation, Retractable glue roller, Infrared heating unit positioned between glue roller & pressure section to improve edge quality, and Pneumatic positioning & Locking. -- Programmable pressure section, with (1) Large driven & (4) Small pneumatically-controlled idler rolls and SIKO Digital units for adjustments. "POWER CONTROL PC 20+" Control, with 600 MHz, 256 MB RAM, USB Port, 1 GB Flash card, Internal modem for remote diagnostic access link, & 12" TFT Flat screen monitor. -- Line control (no limit switches) for workstation functions. -- Heavy-duty feed chain, with 2.2 kW (3 HP) Motor, Rubber pads, & Automatic chain track lubrication. -- Motorized top pressure beam with 0.14 HP (0.10 kW) Motor. -- Outboard panel support, with Roller guide & 1,000 mm (39.37") Adjustment. -- Sound enclosure.Workstations: -- Front & rear end trim unit, with (2) 1 HP - 12,000 RPM High frequency motors, 0° - 15° Chamfer, & Programmable pneumatic control for straight or chamfer trimming. -- Top & bottom rough trim unit, with (1) 1.86 kW (2-1/2 HP) High frequency motor. -- Top & bottom fine trim unit, with (2) 0.55 kW (3/4 HP) - 11,300 RPM High frequency motors with Electronic brakes, Servo control bevel, 0° - 25° Tilt, Vertical & Horizontal tracing, Servo control (in/out), & DFC Radius cutters. -- Corner rounding unit, with (2) 0.35 kW (1/2 HP) - 10,940 RPM High frequency motors, & Automatic 2-position edge thickness. -- Quick-change top & bottom profile scraping unit for rigid PVC edges, with Digital quick-set system for 2 - 6 mm (0.08" to 0.24") Radius, Pneumatic indexing, Servo control (in/out), & Pneumatically-controlled blow-off nozzle. -- Top & bottom buffing unit, with (2) 0.3 HP - 2,800 RPM Motors and Vertical & Horizontal tilt.Full Servo Edgebander, with Pre-Mill, Corner Rounding, Pre-Melt, $5,000 Package of Almost New Diamond Pre-Mill Heads, New

Call for Price

BRANDT OPTIMAT KDN 650 C Edgebander, with Corner Rounding, Pre-Melt, & 8,654 Hrs. (As of 6/2/22) Specifications: -- Edgebanding thickness 0.4 - 8 mm (0.02" - 0.31"). -- Panel thickness 8 - 55 mm (0.31" - 2.17"), Min. panel width 65 mm (2.56"), Min. panel length 160 mm (6.30"). -- Feed speeds 11/14 FPM (36/46 FPM). -- Working height 950 mm (37.40").Equipped with: -- 32-1/2" Dia. Coil table. -- Automatic magazine. -- 3 mm (0.12") Guillotine. -- "Quick-Melt" Hot melt glue unit, with Heat-up time: Approx. 12 min., Pre-melt hopper feed, Quick-change hopper & tank for color changes, Reversible glue applicator roller rotation, & Retractable glue roller. -- Pressure section, with (1) Large driven & (3) Small pneumatically-controlled idler rolls. -- "POWER CONTROL PC 20+" Control, with 600 MHz, 256 MB RAM, USB Port, 1 GB Flash card, Internal modem for remote diagnostic access link, & 12" TFT Flat screen monitor. -- Line control (no limit switches) for workstation functions. -- Feed chain, with 2.2 kW (3 HP) Feed motor & Automatic chain track lubrication. -- Digital height indicator. -- Sound enclosure.Workstations: -- Front & rear end trimming unit, with (2) 0.35 kW (1/2 HP) - 12,000 RPM High frequency motors, 0° - 15° Chamfer, & Programmable pneumatic control for straight or chamfer trimming. -- Top & bottom flush trimming unit, with (2) 0.55 kW (3/4 HP) - 11,300 RPM High frequency motors, 0° - 25° Swivel, & Combination straight/radius cutters. -- Corner rounding unit, with (2) 0.35 kW (1/2 HP) - 10,940 RPM High frequency motors & 3 mm (0.12") Radius insert cutters. -- Top & Bottom Profile scraping unit, with Vertical & Horizontal tracing. -- Top & bottom buffing unit, with (2) 1/4 HP - 1,400 RPM Motors and Vertical & Horizontal tilt.

BRANDT AMBITION 1110 (KDN 110) EDGEBANDER: -- Specifications:0.4 - 3 mm (1/8") Edge thickness cap.; 8 - 40 mm (0.3" - 1.57") panel thickness; 60 mm (2.3") min. panel width; 140 mm (5-1/2") min. length.Equipped with: -- Infeed fence: Adjustable; manual with digital indicator. -- Gluing System: Hot-melt; quick heat-up time; easy maintenance. -- Edge Magazine: Automatic for strip & coil stock; 3 mm PVC guillotine. -- Side Pressure Section: (1) Driven plus (2) idle rollers w/digital readout setting.Workstations: -- End Trimming Unit: Double-motor end trim; (2) x 1/2 HP - 12,000 RPM motors; chamfers 0° - 15°. -- Multi-Trimming Unit: Top/Bottom for flush/bevel/radius trimming; (3) quick setting positions; motors: (2) 1/2 HP - 12,000 RPM; with insert knives. -- Buffing Unit: Top/Bottom; (2) 1/2 HP motors. -- Scrapping Unit: Top/Bottom Scrapping UnitControls:LCD Display: Approx. 2 x 6" with soft keys for fast navigation and operator comfort. Complete with: -- Feed Speed: Fixed; 8MPM (26 FPM); 3 HP feed drive. - Sound enclosure and Scraper collection box. -- Actual Model is BRANDT AMBITION 1110 (KDN 110).

BRANDT AMBITION 1440 FC (KDF 440 C) EDGEBANDER (W/PRE-MILL & CORNER ROUNDING) & 3,359 Hrs.Specifications: -- Edge & Workpiece Capacity: 0.4 - 8 mm (0.016" - 0.31") Edgebanding thickness, 8 - 60 mm (0.31" - 2.36") Panel thickness, 160 mm (6.30") Min. panel length, 70 mm (2.76") Min. panel width.Equipped with: -- Adjustable Infeed Fence: Motorized adjustment with 0.049 kW (0.07 HP) Motor. -- Joint Trimming/Pre-Milling Station: (2) 2.2 kW (3 HP) 12,000 RPM Motors, Left-Hand & Right-hand rotation with Pneumatic jump control for chip-free & clean panel edges. -- Roller Separating Device: 3 mm x 45 mm (0.12" x 1.77") or 1 mm x 55 mm (0.04" x 2.17") Max. roll cutting, 0.4 - 8 mm (0.016" - 0.31") Strip thickness, 3 mm (0.12") PVC Max. coil thickness. -- Hot Melt Glue Application Unit: 6 - 10 kg/Hr. (13 - 22 Lbs./Hr.) Melting capacity (Depending on glue type). -- Workpiece Preheating Unit -- Pressure Zone: (1) Driven & (2) Idle Rollers, Timed pneumatic pressure controlled, Servo motor positioning for programmable edge thickness changeover. -- Feed Speeds: 8 - 14 MPM (27 - 45 FPM), 11 MPM (36 FPM) with Contour trimming. -- BRANDT "POWERTOUCH" Control: With 21" HD LCD Touchscreen monitor.Workstations: -- Front & Rear End Trimming Unit: (2) 0.18 kW (1/4 HP) 12,000 RPM Motors, with 0° - 15° Automatic chamfer, Pneumatic adjustment & Activation/deactivation of edging material overhang using "POWERTOUCH" control. -- Top & Bottom Flush/Chamfer/Radius Trimming Unit: (2) 0.55 kW (3/4 HP) 12,000 RPM Motors, 0° - 25° Automatic tilt, with Horizontal & Vertical Tracing wheels, Brushless multi-axis servo motors for positioning of work-unit & horizontal copy wheels for quick changeover, with (3) Positioning options: Profile 1, Profile 2 & Flush trimming. -- Multi-Functional Trimming Unit: (2) 0.4 kW (1/2 HP) 12,000 RPM Motors for leading & trailing edges vertical corner rounding of panels, Either radius or chamfer cutters can be mounted, 3 mm (0.12") Max. edge thickness. -- Top & Bottom Multi-Profile (PVC) Scraping Unit: (2) Profiles: 1 mm (0.04") & 2 mm (0.08") or 3 mm (0.12") instead of 2 mm (0.08"), Servo control positioning of vertical & horizontal copy wheels, PVC Scrape collection box, Pneumatic adjustment using "POWERTOUCH" control, Pneumatic disengagement. -- Top & Bottom Glue Scraping Unit: Flush on panel surface, with Floating insert knives. -- Top & Bottom Buffing Unit: (2) 0.09 kW (0.12 HP) 2,750 RPM Motors.Complete with: -- Motorized, programmable hold-down pressure beam with 0.12 kW (0.16 HP) Motor, 1.5 kW (2 HP) Feed motor, 32" Diameter Coil table, Padded sound enclosure.NOTE: CPU needs to be replaced.

BRANDT KDF 650 (1650 HIGHFLEX) EDGEBANDER (W/PRE-MILLING & CORNER ROUNDING), with 3,339 Hrs. (As of 10/31/23):Specifications: -- 0.4 - 12 mm (1/2") Edge cap., panel thickness 5/16" - 2-3/16", min. panel length 160 mm (6-3/8") and 65 mm (2-1/2") min. width; line control (NO limit switches) for workstation function. -- Automatic height adjustment with top pressure beam for all work stations, equipped with digital height indicator. -- "PC-16" Program Control with: 21-1/2"; Display, signal infeed light to ensure proper spacing between panels.Equipped with: -- Pre-milling station for cleaning edges of the panel; "Quick change" glue tank for maintenance & glue color change. -- 32"; Dia. Coil table. -- Automatic magazine for strip & coil stock, 3 mm PVC guillotine, (1) drive plus (3) idle roll "pneumatically controlled" pressure sections with digital indicator for quick edge thickness changeover.Workstations: -- End trim (0.33 HP - 12,000 RPM motors), chamfers 0° - 15°; -- Top & bottom flush/bevel/radius trim, bevels 0° - 15° (0.5 HP - 12,000 RPM motors) with insert knives for 2 mm PVC radius. Vertical copy wheels are servo-controlled for quick changeover, programmable from the control panel. -- 2-Motor (4 corners) contour trim for profile corner rounding (two 0.5 HP - 12,000 RPM motors), with insert knives for 2 mm PVC radius. -- Top & bottom scraping for 2 - 6 mm radius, pneumatically controlled blow off nozzles; -- Top & bottom buffing (0.25 HP - 1,400 RPM motors). -- End trim, flush/bevel/radius trim & corner rounding stations have HF motors with electronic brakes; feed chain track speed 42 FPM, 2 HP feed drive.Complete with: -- Operator control panel, PLC (Programmable Logic Control) keypad, and LED readouts; used tooling.NOTE: Actual Model "KDF 650".NOTE: Specifications must be confirmed.Machine Dimensions: 254"; x 50"; x 68"; H.Machine Dimensions with Outboard Panel Support Extended: 254"; x 66"; x 68"; H.

BRANDT OPTIMAT KTD 820 Contour EdgebanderSpecifications: -- Designed for straight, curved (contour), or beveled edgebanding. -- Edgebanding thickness 0.4 - 3 mm (0.02"; - 0.12";). -- Coil cutoff 0.4 - 3 mm (0.02"; - 0.12";) (Max. edge height 45 mm/1.77";). -- Panel thickness 16 - 40 mm (0.63"; - 1.57";). -- Min. radius 25 mm (0.98";). -- Min. panel length 180 mm (7.09";), Min. panel width 100 mm (3.94";). -- Feed speeds 0.7 - 4.2 MPM (2.30 - 13.80 FPM).Equipped with: -- 33"; Dia. Vertical coil table. -- Small glue pot for quick heat-up. -- Magazine for coil or solid strips. -- Guillotine. -- Handheld gluing unit, with Tool balancer & Rotating jib with 8’ Travel. -- (2) 23-1/2"; x 27-1/2"; x 35 H Work tables. -- Large panels can be glued by guiding handheld gluing unit around panel mounted to vacuum suction table. -- Small panels can be glued by guiding panel along gluing unit mounted to table.

--MAKE AN OFFER!--VERY GOOD CONDITION-- BRANDT KDF 650 (1650 HIGHFLEX) Edgebander, with 3,339 Hrs. (As of 10/31/23), Pre-Mill & Corner Rounding Specifications: 0.4 - 12 mm (1/2") Edge cap., panel thickness 5/16" - 2-3/16", min. panel length 160 mm (6-3/8") and 65 mm (2-1/2") min. width; line control (NO limit switches) for workstation function. Automatic height adjustment with top pressure beam for all work stations, equipped with digital height indicator. "PC-16" Program Control with: 21-1/2” Display, signal infeed light to ensure proper spacing between panels. Equipped with: Pre-milling station for cleaning edges of the panel; "Quick change" glue tank for maintenance & glue color change. 32” Dia. Coil table. Automatic magazine for strip & coil stock, 3 mm PVC guillotine, (1) drive plus (3) idle roll "pneumatically controlled" pressure sections with digital indicator for quick edge thickness changeover. Workstations: End trim (0.33 HP - 12,000 RPM motors), chamfers 0° - 15°; Top & bottom flush/bevel/radius trim, bevels 0° - 15° (0.5 HP - 12,000 RPM motors) with insert knives for 2 mm PVC radius. Vertical copy wheels are servo-controlled for quick changeover, programmable from the control panel. 2-Motor (4 corners) contour trim for profile corner rounding (two 0.5 HP - 12,000 RPM motors), with insert knives for 2 mm PVC radius. Top & bottom scraping for 2 - 6 mm radius, pneumatically controlled blowoff nozzles; Top & bottom buffing (0.25 HP - 1,400 RPM motors). End trim, flush/bevel/radius trim & corner rounding stations have HF motors with electronic brakes; feed chain track speed 42 FPM, 2 HP feed drive. Complete with: Operator control panel, PLC (Programmable Logic Control) keypad, and LED readouts; used tooling. NOTE: Actual Model "KDF 650". NOTE: Specifications must be confirmed. Machine Dimensions: 254” x 50” x 68” H. Machine Dimensions with Outboard Panel Support Extended: 254” x 66” x 68” H. CURRENCY NOTE: Negotiable Price is listed in U.S. Dollars.

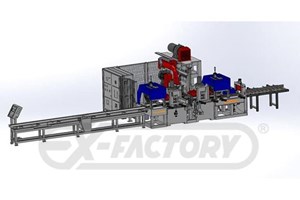

CAM-WOOD HIAT-620-205 WITH 3"; HIGH X 8"; WIDE X 20’ LONG WORKING CAPACITIESTECHNICAL SPECIFICATIONS:Incoming Block Requirements: --Incoming block lengths from 6'' to 39"; (optionnal 122") --Blocks must be at least 50% longer than their width. --Block thickness from 1/2"; to 3 1/2" --Block width from 1"; to 8" - --Assembled lengths from 10’ to 20’ - 24’ Optional --For use with PVAC adhesives --Works equally well with soft & hardwoods. --Moisture content preferred from 8% to 12% --Blocks should be surfaced (4) sides to ± 0.2 mm with 90° right-angle corners. To be supplied by the customer: --Electric power supply to electrical cabinet --Constant voltage with deviations of 5% or less --Temperature range for computer control should not exceed 95°F. --Maximum humidity for computer control system under 65% --Hydraulic oil --Skilled operating and maintenance personnel --Motor Control Center with under-voltage and overload protection; includes UL and CSA approved electrical components. Electric parts only, not the complete machine. --Total electricity demand: 63.75 KW, 85 HP --30 HP Compressor with a 50-to-60-gallon Air Receiver PRODUCTION CAPACITIES:Shaper Capacity: --Shift = 480 minutes --Finger length to buyer’s requirement --As an example: 1-1/2"; X 5/1/2"; X 24"; average finished block size at the Shapers --Shaper max. speed of (3) table strokes per minute --Table cycles will change as block widths become “wider"; or “taller"; at the Shapers --Table accepts up to (16) blocks when vertical finger jointing 1-1/2"; X 5/1/2"; example blocks. --Table accepts up to (4) blocks when horizontal finger jointing 5-1/2"; x 1-1/2"; example blocks.Press Capacity: --Assembly Press w/2 operators: -- (4) Table loads per min. x 20’ lengths x 480 min. per shift x 0.8 rate of utilization = 30,720 lineal feet per shift OR 36,864 lineal feet per shift with 24’ Press)Production Calculations: --VERTICAL Finger Jointing w/2 operators: -- Capacity of the shaper when finger jointing 1-1/2"; x 5-1/2"; x 2’ long blocks: (3) tables stroke per minute X 16-blocks per table load X 2’ average infeed block length x 480 minutes per shift X 0.8 rate of utilization = 36,864 lineal feet per shift (63.34 M³) --HORIZONTAL Finger Jointing w/2 operators: -- Capacity of the shaper when finger jointing 5-1/2"; x 1-1/2"; x 2’ long blocks: (3) table strokes per minute X 4 blocks per table load x 2’ average infeed block length x 480 minutes per shift X 0.8 rate of utilization = 9,216 lineal feet per shift (19.46 M³) NOTE: Capacity is maximum as shown at Assembly Section and is dependent on blocks thru the Shapers System consists of

Call for Price

CAM-WOOD IAT 620-150H INVERTER DRIVEN FINGER JOINT SYSTEM 3" X 6":Lay-Up and Block-Staging Infeed Conveyor: -- 24" Wide x 31.5" long belt conveyor powered with 1/2 HP motors. Conveyor is controlled by the operating and system. Feeds at a constant rate of 180 FPM. Block delivery is controlled by the operator and machine system criteria to feed the Shaper. The conveyor facilitates keeping the system full and productive. FSR-62I Right Hand Inverter Type Finger Joint Shaper: -- Feed table is 24" wide and accepts blocks from 6" wide x up to 31.5" long x 5/8" to 6" wide. Shaper spindle is driven by a 20 HP motor and is equipped with provisions for vertical adjustment of 20 mm up and 20 mm down. Spindle diameter is 50 mm and runs at 6,600 RPM. 8-1/4"; maximum shaper cutterhead diameter - without knives. 10 HP - 4,800 RPM Cutoff and trim saw; accepts 10" dia. x 100 tooth x 5 mm blades. 2 HP - 2,850 RPM Scoring saw, accepts 7" dia. x 50 tooth x 5 mm blades. Table movement is Inverter driven; powered by a 3 HP + 3 HP inverter motor with cycle speeds from 1 to 4 cycles/Min. Motor senses load and varies travel speed as needed. Speed is also controlled by system criteria STC-62A Single Table Transfer Conveyor to the 2nd (Left Hand) Shaper: -- 24" Wide x 31.5" long belt conveyor. Powered with (1) 1/2 HP motor. Controlled by system criteria. Feeds at a constant rate of 180 FPM. FSL-62I Left Hand Inverter Type Finger Joint Shaper with Glue Extruder: -- Feed table is 24" wide and accepts blocks from 6" up to 31.5" long x 5/8" to 6" wide. Shaper spindle is driven by a 20 HP motor. Spindle diameter is 50 mm and runs at 6,600 RPM. 8-1/4" maximum shaper cutterhead diameter - without knives. 10 HP - 4,800 RPM Cutoff and trim saw; accepts 10" dia. x 100 tooth x 5 mm blades. 2 HP motor powers a top and a 2nd 2 HP motor powers a bottom scoring saw, both running at 2,850 RPM; accepts 7" dia. x 50 tooth x 5 mm blades. Conveyer powered by 1/2 HP motor. Table movement is Inverter driven; powered by a 3 HP + 3 HP inverter motor with cycle speeds from 1 to 4 cycles/Min. Motor senses load and varies travel speed as needed. Speed is also controlled by system criteria Injection Type Glue Applicator: -- Extrudes adhesive into the fingers without the messy runoff associated with glue rollers. 6" Comb height is standard. Finger pitch 4 mm, 10 - 12 mm finger length is standard equipment (special sizes available as optional equipment) STC-62A Single Table Conveyor Belt to the Assembly Section: -- 24" Wide x 31.5" long belt conveyor. Powered with (1) 1/2 HP motor. Controlled by system criteria. Feeding at a constant rate of 180 FPM. FJ-500A (198") Assembly Press with Cut-Off Saw: -- Capacity from 1" to 6"; wide x 1/2" to 3" high x and from 6' to 16-1/2' long. A 2 HP motor powers the upper and a 2nd 2 HP motor powers lower pre-assembly/crowder rolls. With 5 HP infeed inverter drive. In-feed speed from 30 to 230 FPM. Speed is controlled by system criteria. 5 HP - 2,85

CAM-WOOD FSM-460AX Finger Joint ShaperSingle Finger joint Shaper with 8" min. and unlimited max. block length; 4" max. block thickness, maximum timber height to feed into assembly press is 3"; 18" max. block width (horizontal joint only); 18" table working width.Equipped with: -- Shaper spindle powered by 10 HP belt drive motor with 50 mm dia. spindle turning at 5,500 RPM; 160 mm (6.3") max. dia. cutter. -- Trim-saw powered by 5 HP direct drive motor at 2,850 RPM and a 1" dia. saw spindle; swings 180 mm (7") max. blade dia. -- Table cycles 2 to 4 per Min via the hydraulic system with a 2 HP hydraulic power unit. Includes 5" dia. dust outlet.Features: -- Manual Fingerjointer performs end trimming and shaping functions on right and left end of blocks. -- Air-operated clamp holding blocks firmly in place. After the workpiece is clamped, the table feeds past the saw and shaper spindles to perform trimming and finger-joint operations; trim saw cuts blocks exactly 90° ends. -- Shaper spindle is precision-constructed for cutting fingers accurately; swings up to 6" dia. tooling. -- Spindle height adjustment is displayed on the dial readout for easy adjustment. -- Table travels on a precision linear guide for stability; table traverse driven by hydraulic power system smooth and accurate block feeding. -- Variable feed speed permits proper feed for hard or soft wood. -- Cast iron frame and table for durability.

CAM-WOOD MODEL FSG-150X Manual FINGER JOINT GLUE APPLICATOR -- Manual operation of sliding table ; Specification: -- Glue roller type -- Working width 24" maximum -- Working thickness 6" -- Glue roller drive 1/2 HP with reducer -- Standard clus height 4"

CAM-WOOD TYPE F1, MODEL FAH 8" X 30’ HORIZONTAL FULLY AUTOMATIC FINGER JOINT SYSTEM - SINGLE CHAIN TYPEMECHANICAL SPECIFICATIONS FOR THE FEED SYSTEM: -- Operating speed: 120 to 150 lugs/Min -- Intermittent feed motor: 2 HP + 1:25 -- Feed chain motor: 30 HP (20 kW) Servo Drive (C2) MECHANICAL SPECIFICATIONS: RIGHT-SIDE SHAPER: -- Cutterhead Motor: 25 HP -- Spindle size: 2-3/4"; (70 mm) -- Maximum cutter head body diameter: 10"; -- Cutterhead speed: 5,500 RPM at 60 Hz -- Trim Saw Motor: 15 HP -- Trim Saw blade size: 12"; (305mm) x 80 Tooth x 5mm kerf -- Cut-off saw Speed: 4,300 RPM -- Scoring saw motor: 3 HP -- Scoring saw blade: 7"; (180mm) x 50 Tooth x 5mm -- Scoring saw spindle speed: 4,200 RPM -- Holddown rise and lower motor: 1/2 HP (C3) MECHANICAL SPECIFICATIONS: LEFT-SIDE SHAPER: -- Cutterhead Motor: 25 HP -- Spindle size: 2-3/4"; (70 mm) -- Maximum cutter head body diameter: 10"; -- Cutterhead speed: 5,500 RPM at 60Hz -- Trim Saw Motor: 15 HP -- Trim Saw blade size: 12"; (305 mm) x 80 Tooth x 5 mm kerf -- Cut-off saw Speed: 4,300 RPM -- Scoring saw motor: 3HP -- Scoring saw blade: 7"; (180 mm) x 50 Tooth x 5 mm -- Scoring saw spindle speed: 4,200 RPM -- Holddown rise and lower motor: 1/2 HP -- Glue Application by GLUE COMB -- Standard glue height: 6"; High, 3.8 mm pitch 3.8 mm. Finger lengths from 10 to 12 mm (Other lengths available) (K) MECHANICAL SPECIFICATIONS: SHAPER OUT-FEED: -- Speed: 230 FPM -- Feed Motor: (1) 3 HP -- Vacuum device blower with 3"; Vacuum port: 5 HP (G) MECHANICAL SPECIFICATIONS: PRE-JOINT ASSEMBLY: --Feed chain drive: (2) 3 HP motors --In-feed Inverter: (1) 7-1/2 HP --Chain type: Flat top double chain --Feeding speeds from 30 to 300 FPM (H) MECHANICAL SPECIFICATIONS: 30’ (9.3M) ASSEMBLY PRESS: --Working dimension: 1"; to 8"; wide x 0.60"; to 2 3/8"; high x up to 30’ long --Upper & lower roll power: (2) 2 HP motors --In-feed Inverter: 7-1/2 HP --In-feed speed: 30 to 300 FPM --PROGRAMMABLE Cut-off saw power: 5 HP --Cut-off Blade dimensions: 14"; Dia. x 120 Tooth x 1"; bore --Cut-off saw speed: 2,850 RPM --Hydraulic power: 5 HP (With high speed oil tank) --Cycle Speed: 1 to 8 Cy/MinPRODUCTION CAPACITY - PARAMETERS: -- Based on a 480-minute shift -- Finger length to customer’s specifications -- Average infeed length at the shaper section is 20"; --A verage block cross section is 2"; x 4"; -- Chain speed at the Shaper sections is 150 lugs/Min -- Press capacity is (8) 30’ loads per minute (maximum) CAPACITY OF THE SHAPERS WHEN FINGER JOINTING 2"; X 4"; x 20" BLOCKS -- (120) Blocks per minute -- x 20"; Average infeed length -- x 480 Minutes per shift -- x 0.8 Rate of utilization = 76,800 lineal feet per shift CAPACITY OF THE PRESS ASSEMBLING 30’ LENGTHS: -- (8) Assembled lengths per minute -- x 20’ Per minute -- x 480 Minutes per shift -- x 0.8 Rate of utilization = 66,440 lineal feet per shift -- NOTE: If using the cutoff saw for multi-section pressin

CAM-WOOD TYPE F1, MODEL FAH 8" X 40’ AUTOMATIC HORIZONTAL FINGER JOINT SYSTEM - SINGLE CHAIN TYPE (including Feeding System from Optimizing Saw)Technical Specifications: -- Working thickness: 17 mm to 60 mm (.66" to 2 3/8") -- Working width: 25 mm to 205 mm ( 1" to 8") -- Maximum finish length: 12 Meters ( 40') -- Glue type: PVAC -- Timber moisture: 8% to 12% -- Infeed quality must be S4S with tolerance +/- 02 mm, wood need 90° right angle and straight MECHANICAL SPECIFICATIONS FOR THE FEED SYSTEM: -- Operating speed: 120 to 180 lugs/Min -- Intermittent feed motor: 2 HP + 1:25 -- Feed chain motor: 30 HP (20 kW) Servo Drive (C2) MECHANICAL SPECIFICATIONS: RIGHT-SIDE SHAPER: -- Cutterhead Motor: 25 HP -- Spindle size: 2-3/4"; (70 mm) -- Maximum cutter head body diameter: 10"; -- Cutterhead speed: 5,500 RPM at 60 Hz -- Trim Saw Motor: 15 HP -- Trim Saw blade size: 12"; (305 mm) x 80 Tooth x 5 mm kerf -- Cut-off saw Speed: 4,300 RPM -- Scoring saw motor: 3 HP -- Scoring saw blade: 7"; (180 mm) x 50 Tooth x 5 mm -- Scoring saw spindle speed: 4,200 RPM -- Holddown rise and lower motor: 1/2 HP (C3) MECHANICAL SPECIFICATIONS: LEFT-SIDE SHAPER: -- Cutterhead Motor: 25 HP -- Spindle size: 2-3/4"; (70 mm) -- Maximum cutter head body diameter: 10"; -- Cutterhead speed: 5,500 RPM at 60 Hz -- Trim Saw Motor: 15 HP -- Trim Saw blade size: 12"; (305 mm) x 80 Tooth x 5 mm kerf -- Cut-off saw Speed: 4,300 RPM -- Scoring saw motor: 3 HP -- Scoring saw blade: 7"; (180 mm) x 50 Tooth x 5 mm -- Scoring saw spindle speed: 4,200 RPM -- Holddown rise and lower motor: 1/2 HP -- Glue Application by GLUE COMB -- Standard glue height: 6"; High, 3.8 mm pitch 3.8 mm. Finger lengths from 10 to 12 mm (Other lengths available) (K) MECHANICAL SPECIFICATIONS: SHAPER OUT-FEED: -- Working size: Length 150 mm to 900 mm ( 6" to 35-7/16"); Width 25 to 205 mm (1" to 8") -- Speed: 70 m/Min ( 230 FPM) -- Infeed inverter : (1) 3 HP -- Vacuum device blower with 3"; Vacuum port: 5 HP (G) MECHANICAL SPECIFICATIONS: PRE-JOINT ASSEMBLY: -- Working size: Thickness 17 mm to 60 mm (5/8" to 2,3/8"); Width 25 mm to 205 mm (1" to 8") --Feed chain drive: (2) 3 HP motors --In-feed Inverter: (1) 7-1/2 HP --Chain type: Flat top double chain --Feeding speeds from 10 to 90 m/Min (32 to 292 FPM) (H) MECHANICAL SPECIFICATIONS: 40’ (12 M) ASSEMBLY PRESS: --Working dimension: 3/4"; to 8"; wide x 0.60"; to 2-3/8"; high x up to 40’ long --Upper & lower roll power: (2) 2 HP motors --In-feed Inverter: 7-1/2 HP --In-feed speed: 10 m to 70 m/Min (32 to 227 FPM) --PROGRAMMABLE Cut-off saw power: 5 HP --Cut-off Blade dimensions: 14"; Dia. x 120 Tooth x 1"; bore --Cut-off saw speed: 2,850 RPM --Hydraulic power: 5 HP (With high-speed oil tank) --Cycle Speed: 1 to 6 Cy/MinPRODUCTION CAPACITY - PARAMETERS: -- Based on a 480-minute shift -- Finger length to customer’s specifications -- Average infeed length at the shaper section is 500 mm (20";) --Average block cross-

CAM-WOOD TYPE F1, MODEL FAH 8" X 20’ AUTOMATIC HORIZONTAL FINGER JOINT SYSTEM - SINGLE CHAIN TYPE (including Feeding System from Optimizing saw)Technical Specifications: -- Working thickness: 17 mm to 60 mm (0.66" to 2-3/8") -- Working width: 25 mm to 205 mm ( 1" to 8") -- Maximum finish length: 6.2 Meters ( 20') -- Glue type: PVAC -- Timber moisture: 8% to 12% -- Infeed quality must be S4S with tolerance +/- 02 mm, wood need 90° right angle and straight MECHANICAL SPECIFICATIONS FOR THE FEED SYSTEM: -- Operating speed: 120 to 180 lugs/Min -- Intermittent feed motor: 2 HP + 1:25 -- Feed chain motor: 30 HP (20 kW) Servo Drive (C2) MECHANICAL SPECIFICATIONS: RIGHT-SIDE SHAPER: -- Cutterhead Motor: 25 HP -- Spindle size: 2-3/4"; (70 mm) -- Maximum cutter head body diameter: 10"; -- Cutterhead speed: 5,500 RPM at 60 Hz -- Trim Saw Motor: 15 HP -- Trim Saw blade size: 12"; (305 mm) x 80 Tooth x 5 mm kerf -- Cut-off saw Speed: 4,300 RPM -- Scoring saw motor: 3 HP -- Scoring saw blade: 7"; (180 mm) x 50 Tooth x 5 mm -- Scoring saw spindle speed: 4,200 RPM -- Holddown rise and lower motor: 1/2 HP (C3) MECHANICAL SPECIFICATIONS: LEFT-SIDE SHAPER: -- Cutterhead Motor: 25 HP -- Spindle size: 2-3/4"; (70 mm) -- Maximum cutter head body diameter: 10"; -- Cutterhead speed: 5,500 RPM at 60 Hz -- Trim Saw Motor: 15 HP -- Trim Saw blade size: 12"; (305 mm) x 80 Tooth x 5 mm kerf -- Cut-off saw Speed: 4,300 RPM -- Scoring saw motor: 3 HP -- Scoring saw blade: 7"; (180 mm) x 50 Tooth x 5 mm -- Scoring saw spindle speed: 4,200 RPM -- Holddown rise and lower motor: 1/2 HP -- Glue Application by GLUE COMB -- Standard glue height: 6"; High, 3.8 mm pitch 3.8 mm. Finger lengths from 10 to 12 mm (Other lengths available) (K) MECHANICAL SPECIFICATIONS: SHAPER OUT-FEED: -- Working size: Length 150 mm to 900 mm ( 6" to 35-7/16"); Width 25 to 205 mm (1" to 8") -- Speed: 70 m/Min ( 230 FPM) -- Infeed inverter : (1) 3 HP -- Vacuum device blower with 3"; Vacuum port: 5 HP (G) MECHANICAL SPECIFICATIONS: PRE-JOINT ASSEMBLY: -- Working size: Thickness 17 mm to 60 mm (5/8" to 2,3/8"); Width 25 mm to 205 mm (1" to 8") --Feed chain drive: (2) 3 HP motors --In-feed Inverter: (1) 7-1/2 HP --Chain type: Flat top double chain --Feeding speeds from 10 to 90 m/Min (32 to 292 FPM) (H) MECHANICAL SPECIFICATIONS: 20’ (6.2 M) ASSEMBLY PRESS: --Working dimension: 3/4"; to 8"; wide x 0.60"; to 2-3/8"; high x up to 20’ long --Upper & lower roll power: (2) 2 HP motors --In-feed Inverter: 7-1/2 HP --In-feed speed: 10 m to 70 m/Min (32 to 227 FPM) --PROGRAMMABLE Cut-off saw power: 5 HP --Cut-off Blade dimensions: 14"; Dia. x 120 Tooth x 1"; bore --Cut-off saw speed: 2,850 RPM --Hydraulic power: 5 HP (With high-speed oil tank) --Cycle Speed: 1 to 6 Cy/MinPRODUCTION CAPACITY - PARAMETERS: -- Based on a 480-minute shift -- Finger length to customer’s specifications -- Average infeed length at the shaper section is 500 mm (20";) --Average block cros

CAM-WOOD Continuous in-line Long Board Vertical Finger Joint System, Model "UCT-305"Up to 12"; Wide x 4-1/4" Thick x Unlimited Assembled Length System Specifications: -- Incoming board lengths from 39"; to 236" (1,000 mm - 6,0000 mm). -- Board widths from 2"; to 12"; (50 mm - 305 mm). -- Board thickness from 1" to 4.3"; (25 mm - 110 mm). -- Board out-feed length 40’. (could be increased with an outfeed conveyor) -- Glue type to be used: PVAC. (Glue pump and applicator not included) -- Board species: SOFTWOOD and HARDWOOD. -- Board moisture content: 8% to 12%. -- Infeed board qualities: Lumber runs best on Finger Jointers when surfaced on (4) sides (S4S) (Tolerance +/- .2 mm (.008"). System prefers straight boards with 90-degree corners. UCT-305 Mechanical Specifications: -- Top infeed feed rolls powered with (2) 2HP motors. -- Bottom infeed feed rolls powered with (2) 2 HP motors. -- In-feed Inverter with (2) 7.5 HP motors. -- Auxiliary conveyor wheel with 2.6 HP servo motor. -- Top Shaper Spindle powered with a 30 HP motor. -- Bottom Shaper Spindle powered with a 30 HP motor. -- Maximum Cutterhead length, 12“(305 mm). -- Maximum Cutterhead diameter, 6.3“(160 mm). -- Typical cutter pitch, 4.0 mm. Length, 10 mm - 12 mm (Other sizes available). -- Shaper spindle moving power by 2.6 HP Servo Motor. -- In-feed speed from 32 to 295 FPM (10 ~90 m/Min). -- Outfeed cut-off saw motor, 10 HP. -- Cut-off sawblade, 24“ dia x 120 teeth (included). -- Cut-off sawblade speed, 2,850 RPM. -- Hydraulic pump power, 30 HP. -- Outfeed conveyor, (2) 2 HP drives. -- Top outfeed feed rolls powered with (2) 2 HP motors. -- Lower outfeed feed rolls powered with (2) 2HP motors. -- Out-feed Inverter with (2) 7.5 HP motors. -- Glue injection Glue Applicator for Standard PVAC glue. (glue pump not included) -- Hydraulic oil tank with 150-gal capacity (oil not included)Outfeed options: -- Outfeed roller conveyor 20'' X 8' long Additional: $ 4,890 per sectionNot included with the machine: -- Cutter heads for the finger jointer (we can provide a quote) -- Gluing system with pump and nozzle Optional Cross Infeed Conveyor System:Optional Automatic 20 ft Cross InfeedPower Conveyor System Working size L = 1000 MM ~ 6000 MM, W= 50 ~ 305 MM, T=25 ~ 110 MM (Length 39" - 236" X Width 2" -12", Thickness: 1" to 43.3")Infeed roller Conveyor 3 HP1Cross feeding system 3 HP1Feeding speed of 15 M/min (48'/Min.)Storage area width 2500 mmAdditional cost: $61,990Glue Pump Option: -- Graco 1K PUR Glue SystemAdditional cost: $ 48,990NOTE: Training, installation & tooling not included TO BE PROVIDED LOCALLY -- Electric power supply to Motor Control Center -- Constant voltage (voltage deviations max.: 5%) -- Temperature range for computer control should not exceed 95°F. -- 65% Maximum relative air humidity for computer control system --Dust exhaust system: (V=30M/S at a low pressure of 12M BAR) --Compressed air connection to machinery: 7~8 KG/cm² – 8 BAR --Electri

Call for Price

CAM-WOOD IAT 620-100HX INVERTER DRIVEN FINGER JOINT SYSTEM 3" X 6" X 16.5 feet long medium capacity Finger Jointing SystemIncoming Block Specifications: -- Incoming block lengths from 6"; to 31.5"; -- Blocks must be at least 50% longer than their width. -- Block thickness from 1/2"; to 3" -- Block width from 1"; to 6" -- Assembled lengths from 10’ to 16’ (Options 20’ or 24’) -- For use with PVAC adhesives (glue pump and nozzle not included) -- Works equally well with soft and hardwoods. -- Moisture content from 8 to 12% -- Blocks to be surfaced on (4) sides through a Moulder or 4-sided Planer to ± 0.2 mm with 90° right angle corners.Lay-Up and Block-Staging Infeed Conveyor: -- 24" Wide x 31.5" long belt conveyor powered with 1/2 HP motors. The conveyor is controlled by the operating system. Feeds at a constant rate of 180 FPM. Block delivery is controlled by the operator and machine system criteria to feed the Shaper. The conveyor facilitates keeping the system full and productive. FSR-62I Right Hand Inverter Type Finger Joint Shaper: -- Feed table is 24" wide and accepts blocks from 6" to 31.5" long -- 5/8" to 6" width -- 1/2" to 3" thickness -- Shaper spindle is driven by a 20 HP motor and is equipped with provisions for vertical adjustment of 20 mm up and 20 mm down. Spindle diameter is 50 mm and runs at 6,600 RPM. 6.3"; (160 mm) maximum shaper cutterhead diameter (cutter head not included) -- 5 HP - 4,800 RPM Cutoff and trim saw; accepts 10" dia. x 100 tooth x 5 mm blades. -- 2 HP - 2,850 RPM Scoring saw, accepts 7" dia. x 50 tooth x 5 mm blades. -- Conveyor powered by 1/2 HP motor. -- Table movement is inverter driven; powered by a 3 HP inverter motor with cycle speeds from 1 to 4 cycles per minute. Motor senses load and varies travel as needed. TC-62 Single Table Transfer Conveyor to the 2nd (Left Hand) Shaper: -- 24" Wide x 31.5" long belt conveyor. Powered with (1) 1/2 HP motor. Controlled by system criteria. Feeds at a constant rate of 180 FPM. FSL-62I Left Hand Inverter Type Finger Joint Shaper with Glue Extruder: -- Feed table is 24" wide and accepts blocks from 6" to 31.5" long -- 5/8" to 6" width. -- 1/2" to 4" thickness -- A 20 HP motor drives shaper spindle. Spindle diameter is 50 mm and runs at 6,600 RPM. 6.3" (160 mm) Maximum shaper cutterhead diameter (cutter head not included). -- 10 HP - 4,800 RPM Cutoff and trim saw; accepts 10" dia. x 100 tooth x 5 mm blades. -- 2 HP motor scoring saw, running at 2,850 RPM; accepts 7" dia. x 50 tooth x 5 mm blades. -- Conveyer powered by 1/2 HP motor. -- Table movement is Inverter driven; powered by a 3 HP inverter motor with cycle speeds from 1 to 4 cycles/Min. Motor senses the load and varies travel as needed. Speed is controlled by system criteria. Included Injection Type Glue Applicator: -- Extrudes adhesive into the fingers without a messy runoff. 4" Comb height is standard. -- Finger pitch 4 mm, 10 - 12 mm finger length is standard equipm

CAM-WOOD FJ-17 (FM) 6" X 16' Long Semi-Automatic Finger Jointer System(4) Version possible on this model. Choose the one that suits your needsTechnical Specifications:Incoming Block Requirements: -- Incoming block lengths No Limit (Manual Loaded). Blocks must be at least 50% longer than their width. -- Block thickness from 1/2"; to 3" -- Block width from 1"; to 6" -- Assembled lengths from 8’ to maximum 16’ or (20’ Options Add Extra ...$5,675.00) or 24’ (Options Add Extra ...$11,450.00) -- For use with PVAC adhesives Glue pump is not included -- Works equally well with soft and hardwood Blocks. Moisture content from 8 to 12% -- Blocks to be surfaced (4) sides through a Moulder or 4-sided Planer to ±0.2mm with 90° right angle cornersThis semi-automatic system is offered in (4) different versionsVersion 1: -- Finger Shaper (FSM-460A) + Conveyor (RO-62) x 2 + Assembly Press (FJ-500A) The price: $82,900.001. Semi-Auto Finger Shaper Process the finger at one side 2. Manually flip/turn to the other side and make fingers again at the same shaper,3. Manual blush applied the glue,4. Semi-Automatic finger jointer press The price: $92,150.00Version2: -- Finger Shaper (FSM-460A) + Conveyor (RO-62) x 2 + Manual Gluer (FSH-150) + Assembly Press (FJ-500A) 1. Semi-Auto Finger Shaper Process the finger at one side.2. Manually flip/turn to the other side and make fingers again at the same shaper,3. Manual Glue Spreader applied the glue,4. Semi-Automatic finger jointer pressThe price: $103,250Version 3: -- Finger Shaper with Gluer (FSM-621) + Conveyor (RO-62) x 2 + Assembly Press (FJ-500A) 1. Semi-Auto Finger Shaper Process the finger at one side.2. Manually flip/turn to the other side and make fingers again at the same shaper,3. Automatic Glue Spreader applied the glue at the second finger process,4. Semi-Automatic finger jointer press The price: ...$116,600.00Version 4:Finger Shaper (FSM-460A) + RO-62 x 3 + Finger Shaper with Gluer (FSM-621) + Assembly Press (FJ-500A)1. Semi-Auto Finger Shaper Process the finger at one side.2. Push to the next (2nd) Semi-automatic finger shaper with Auto Glue Spreader and applied the glue at the other side,3. Semi-Automatic finger jointer pressThe price: ...$ 159,900Description of Each Unit:FSM-460A Semi-auto finger shaper (Air-hydraulic type) -- Working timber width (Horizontal Direction); 1"; to 6"; -- Maximum timber total width fit on working table 18"; -- Maximum working height (Vertical direction); 4"; -- Maximum timber thickness (Height feed into assembly press); 3"; -- Working timber length; No Limit (Timber length must be at least 50% longer than the timber width to be processed.) -- Trim saw/Hogging blade 180 mm x 50T x 5 mm x 1 pcs. Trim/Hogging saw speed; 2,850 RPM -- Trim/Hogging saw motor 5 HP x 1 -- Finger shaper motor; 10 HP x 1 . Finger spindle Speed; 5,500 RPM. Spindle size; 50 mm, OD of finger cutter; OD160 mm -- Table movement by pneumatic–hydraulic cylinder -- Cycle time