704-841-2001

Backed with a massive machinery database considered to be “the blue book” of woodworking machinery), EX-FACTORY Auctions provides a complete assessment of your equipment and allows you to interact with the market real-time in our dynamic Online Auction!

2032 Results Found

704-841-2001

ORIGINAL 3691-01-7 Overhead Rail Panel SawSpecifications: -- Sturdy welded steel frame for saw head and beam arm; 7.5 HP motor; 1" dia. arbor; 1-3/8" long arbor; saw head with automatic electro-mechanical motor brake. -- 20-1/2" Max. blade dia.; 8" max. cutting depth @ 90°; 4" @ 45°; 60" long x 1" max. crosscut cap. -- Complete with: -- 36" x 60" MDF table; heavy gauge steel base & legs for solid support. -- Includes: -- Upper & lower blade guards; magnetic starter and overload protection.

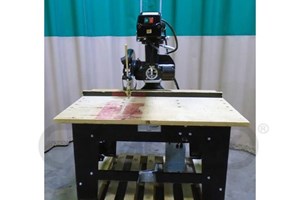

ORIGINAL 3512-03 RADIAL ARM SAW (Contractor Series)The Contractor Duty Series is an industrial rated machine that has the versatility to crosscut, bevel cut, miter cut, and swivel to a rip position to cut down panels precisely and accurately. These machines are well suited for cutting off up to 3"; material, as well as cutting off 24"; wide panels for squaring shelving and doors and other similar applications. -- Specifications: -- 3 HP TEFC Saw motor; 12" dia. blade; 1" x 2-3/16" saw arbor; 3-1/16" thickness cap. @ 90°, 1-1/4" @ 45°; 24-1/4" crosscut cap. with 1" stock; 21-1/4" with 3" stock; 16" max. miter cut @ 45° with 1" stock; 34-15/16" rip cap. -- Features: -- Swivel arm for miter cuts, swivel motor for bevel cuts; indexing yoke to 90° for rip cutting panels; saw head with automatic motor brake and automatic spring return; positive locking device for tilting; upper and lower blade guards with anti-kickback attachment. -- Complete with: -- 34" x 26" MDF table; sturdy powder coated cast iron frame; heavy gauge steel base and support legs. -- Optional: --12" x 36 or 60-Tooth x 1" Bore saw blade; OS Series manually adjustable measuring systems; OS Series material handling roller and flat tables; dust collection hoods; key access limiting switch and emergency stop switch.

ORIGINAL 3546 RADIAL ARM SAW (Heavy Duty Series)The Heavy Duty Series is a very precise machine made for the rigors of every day industrial use. Straight, miter, bevel and compound bevel cutting in a heavy gauge steel powder coated frame & legs. Specifications: 5 HP TEFC Saw motor; 16" dia. blade; 1" x 2-3/16" saw arbor; 4-15/16" thickness cap. @ 90°, 2" @ 45°; 24" crosscut cap.; 15-1/2" max. miter cut @ 45°; 37-7/8" rip capacity. Features: -- Swivel arm for miter cuts, swivel motor for bevel cuts; indexing yoke to 90° for rip cutting panels; saw head with automatic motor brake and automatic spring return; positive locking device for tilting; upper and lower blade guards with anti-kickback attachment. Complete with: -- 42-1/2" x 31-1/4" MDF table; sturdy powder coated cast iron frame; heavy gauge steel base and support legs. Optional: -- 16" x 60-Tooth x 1" Bore saw blade; pneumatic clamping systems; power carriage feed; 14" & 22" wide roller tables.

ORIGINAL 3558 RADIAL ARM SAW (Super Duty Series)The Super Duty Series is the ultimate workhorse of the industry, capable of operating 2 to 3 shifts per day. Miter & bevel cutting, compound miters and dado operations. Constructed of heavy-duty cast and ductile iron for vibration-free operation. Specifications: -- 7.5 HP TEFC Saw motor; 20" dia. blade; 1" x 3-1/8" saw arbor; 6-1/4" thickness cap. @ 90°, 3-1/4" @ 45°; 32" crosscut cap.; 21-5/8" max. miter cut @ 45°; 48-3/4" rip cap. Features: -- Swivel arm for miter cuts, swivel motor for bevel cuts; indexing yoke to 90° for rip cutting panels; saw head with automatic motor brake and automatic spring return; positive locking device for tilting; upper and lower blade guards with anti-kickback attachment. Complete with: 58" x 50" MDF table; sturdy powder coated cast iron frame; heavy gauge steel base and support legs. Optional: -- 20" x 60-Tooth x 1" Bore saw blade; pneumatic clamping systems; power carriage feed; 14" & 22" wide roller tables.

ORIGINAL 3579-16L Metal Cutting Radial Arm Saw (Super Duty Series)The Super Duty Series is the ultimate workhorse of the industry, capable of operating 2 to 3 shifts per day. Miter & bevel cutting, compound miters and dado operations. Constructed of heavy duty cast and ductile iron for vibration free operation.Specifications: -- 7.5 HP TEFC Saw motor; 16" dia. blade; 1" x 3-1/8" saw arbor; 5" thickness cap. @ 90°, 2" @ 45° bevel; 32" crosscut cap.; 21-5/8" max. miter cut @ 45°. -- Features: -- Swivel arm for miter cuts, swivel motor for bevel cuts; indexing yoke to 90° for rip cutting panels; saw head with automatic motor brake and manual chain feed assembly; positive locking device for tilting; upper and lower blade guards with anti-kickback attachment. -- Complete with: -- The Metal Cutting Series comes with the standard t-slot aluminum extruded top, allowing easy to attach aluminum fence, clamping systems, table surface options, as well as your own clamping jigs or cutting fixtures. These all come mounted to a extruded leveling frame for easy leveling of the entire table assembly throughout the life of the machine. -- Available Options: -- Power feed saw head; pneumatic clamping systems; Mist Coolant System (manual for non-ferrous cutting); blade.

$7,950

ORIGINAL - 3551, ...Radial Arm SawThe "Original" Radial Arm with: Full 24" crosscut capability. -- Sturdy cast iron frame for saw head and arm.Equipped with: -- 5 HP Single-phase motor with: Magnetic starter and overload protection. -- Saw head with: Automatic motor brake and automatic return. -- Positive locking device for tilting. -- Large 49" x 50" MDF table. -- 16" Blade cap. with: 4-3/8" Material thickness at 90°. -- Features: -- Heavy gauge steel base & legs for solid support. -- Complete upper & lower blade guards and anti-kickback attachment.

ORIGINAL 3579-20L Metal Cutting Radial Arm Saw (Super Duty Series)The Super Duty Series is the ultimate workhorse of the industry, capable of operating 2 to 3 shifts per day. Miter & bevel cutting, compound miters and dado operations. Constructed of heavy duty cast and ductile iron for vibration free operation. Aluminum, Brass, Bronze, Copper, Fiberglass, Lead Sheets, Plastic, Steel. Specifications: -- 7.5 HP TEFC Saw motor; 20" dia. blade; 1" x 3-1/8" saw arbor; 7" thickness cap. @ 90°, 3-3/8" @ 45° bevel; 32" crosscut cap. with 1" stock; 21-5/8" max. miter cut @ 45°. -- Features: -- Swivel arm for miter cuts, swivel motor for bevel cuts; indexing yoke to 90° for rip cutting panels; saw head with automatic motor brake and manual chain feed assembly; positive locking device for tilting; upper and lower blade guards with anti-kickback attachment. -- Complete with: -- The Metal Cutting Series comes with the standard t-slot aluminum extruded top, allowing easy to attach aluminum fence, clamping systems, table surface options, as well as your own clamping jigs or cutting fixtures. These all come mounted to a extruded leveling frame for easy leveling of the entire table assembly throughout the life of the machine. -- Available Options: -- Power feed saw head; pneumatic clamping systems; Mist Coolant System (manual for non-ferrous cutting); blade.

ORIGINAL 3579-22L Metal Cutting Radial Arm Saw (SD Series)SD Series is the ultimate workhorse of the industry, capable of operating 2 to 3 shifts per day. Miter & bevel cutting, compound miters and dado operations. Constructed of heavy duty cast and ductile iron for vibration free operation. Aluminum, Brass, Bronze, Copper, Fiberglass, Lead Sheets, Plastic, Steel. Specifications: -- 7.5 HP TEFC Saw motor; 22.5" dia. blade; 1" x 3-1/8" saw arbor; 8" thickness cap.; 4" @ 45° bevel; 24" crosscut cap. with 3/4" stock; 21-5/8" max. miter @ 45°. -- Features: -- Swivel arm for miter cuts, swivel motor for bevel cuts; saw head features VFD technology; which increases the start-up speed of the blade by over 8 seconds with a slower, smoother start-up that slows and stops the saw over approximately 25 seconds to allow for consistent braking times; positive locking device for tilting; upper and lower blade guards with anti-kickback attachment. -- Complete with: -- The Metal Cutting Series comes with the standard t-slot aluminum extruded top, allowing easy to attach aluminum fence, clamping systems, table surface options, as well as your own clamping jigs or cutting fixtures. These all come mounted to an extruded leveling frame for easy leveling of the entire table assembly throughout the life of the machine. -- Available Options: -- Power feed saw head; pneumatic clamping systems; Mist Coolant System (manual for non-ferrous cutting); blade.

Call for Price

ORMA NPC DIGIT 36/16, ...5' x 12' Electric Hot Press For Solid Surface & Panel Dye SublimationSide Opening Press designed to work with Dye Sublimation materials to print into Solid Surfaces, as well as Panels that can receive Dye Sub Inks. The Press has (6) Pressing Cylinders, 70 mm dia. (2-3/4"), and an opening of 400 mm (15-3/4").Electric Heated Platens: -- ELKOM Germany 3,700 x 1,600 x 24 mm ( 145-1/2" x 63" x 1") + 19 mm (3/4") Monolux + 19 mm (3/4") V100. -- Each platen requires 31 kW, Voltage 440 V / 3 Ph. / 50/60 Hz. -- Max. working temperature is 180°C (356° F). -- Gold anodized surface; massive, solid top of 12 mm (1/2") thick sheet, flat platen surface without any screw; Heat-up time from room temperature to 160°C (320° F): ca. (45) Minutes.Operator & Machine Controls: -- Integrated CNC operator panel on the front right beam with 6"; KTP600 BASIC SIEMENS color Touch-Screen control. -- Complete with individual programmable electronic control (PLC), central unit CPU, and expansion possibility of inputs & outputs. Hardware by SIEMENS, software by ORMAMACCHINE.Manual controls for : -- Push buttons for Press closing and manual Press opening. -- Emergency lamp and emergency push button. -- General on/off switch. -- Power signal lamp.Digital controls for : -- Automatic adjustment of the requested pressure in bar (with automatic recovery of pressuredecrease) obtained by setting the working pieces area and the desired specific pressure. -- Setting & digital display of working temperature on platens. -- Setting & digital display of pressing time for automatic opening. -- Heating platens on/off. -- Automatic switching on of the platens with the possibility to set every day of the week. -- Possibility to store a max. of (20) working programs (temperature, specific pressure, pressing time, and panel dimensions).Special Features: SILICONE MEMBRANE fitted to the upper platen and fixed all around the Press upper structure by means of fast clamping/unclamping units, helps to balance possible uneven profiles and to protect the Press platens from ink transmission.

ORMA NPC/DIGIT 31/13 Hydraulic Hot Press (Oil Heated Platens)Main Features: -- Press platen dimension 3100 x 1300 mm (122" X 51") -- Max. total thrust 160 T (metric) - 352,000 Lbs -- Pressure over 80% of platen 5.0 Kg/cm² (71 PSI) -- Pressing cylinders (8) Ø 85 mm with 450 mm (17-3/4") stroke -- Movable platen lower (upstroke design) -- Opening 450 mm (17-3/4") -- Loading side 3100 mm (122") side Structure: -- Press structure in steel beams welded together on a precision jigs; locating surfaces are CNC tool machined -- The lower mobile platen and the upper fix platen structure are in beams welded on a precision jigs. -- Double rack and pinion system (both length and crosswise) to grant a perfect platens’ parallelism when the mobile one is moving up/downward. -- Movable platen locking system in order to work safely during the maintenance operations Hydraulic System: -- Hydraulic power unit (HAWE) composed by a double stage pump and a motor which are submersed in the hydraulic oil for a less noisiness and a better lubrication of the rotating parts. Closing stage (high delivery at low pressure) and thrusting stage (low delivery at high pressure). Both pumps are protected by a pressure relief valve. -- This system allows the use of lower consumption motors increasing the efficiency of the plant. -- Unit fitted with control and safety valves located in a group over the hydraulic oil tank lid -- The circuit comes filled with the necessary hydraulic oil to run the press. -- Rams are in steel suitable for hydraulic applications and are designed to work at the max pressure adjustable on the press. Electric System: -- Main control board (SIEMENS components) including: -- Dual timed press closing push buttons; press opening push button. -- Main on/off switch. -- Tension light. -- Emergency push button Operator control, touch screen panel, with: -- 7"; Digital display, SIEMENS "KTP700 BASIC COLOR" equipped with ETHERNET NET for remote assistance connection (it requires access to your Internet + Service pack) to set and control the following functions: -- Setting and display of the working pressure -- Setting and display of the working temperature (presses with electric heater) -- Setting and display of the pressing time for automatic opening -- Setting of the heating plant automatic switching on (presses with electric heater). Possibility of all week days settingpossibility to automatically set the partial use the power consumption of the boiler when it reaches the set temperature (for presses with

$10,900

ORTON - TYPE F, ...Ship Shaper/RouterORTON Type "F" Ship Shaper/Router with: 40" x 60" Table Size. -- 5 HP - 230 Volt, 3-Phase. -- Oil Mist Lubrication. -- Machine "Completely Restored". -- Can be used as a Shaper or Router. -- Comes with: Mandrel with Top Bearing Attachment so the machine can be used as a Tilting Spindle Shaper. -- Also used as a Tilting Spindle Router with: Collet Chuck attachment with: 1" HSS spiral cutter and template guide. -- Heavy-Duty spindle with: BROWN & SHARPE "#11 Tapered Socket" in Spindle. -- Spindle tilts: 30° forward and 45° backward. -- Includes: BROOKS Frequency changer to increase 60-Cycles to 250-Cycles to increase speed of routers to 4,700 RPM. -- Great for cutting changing bevels. -- Approx. weight 3,000 Lbs. -- Lamp & cord NOT included. 5 HP - 230 Volts, 3-phase; in "Excellent Condition." Routers come with: 4 Ft x 14 ft table for clamping down work with patterns; also includes stands. Countertops. Great for cutting multiple pieces without tying up your CNC Router. Routers have been used in 1-Man Shop.

Call for Price

OSAMA SP/RSI-1600 1600 mm (63") Top & Bottom Brush Panel CleanerSpecifications: -- Min. panel length 430 mm (16.93"), Panel thickness 0 - 100 mm (3.94"). -- Feed speed 22 MPM (72 FPM).Equipped with: -- 290 mm (11.42") Dia. Top & bottom brush rolls, with 0.6 mm (0.02") Dia. Black nylon bristles.Available at additional cost: -- Spare pair of brushes.NOTE: This machine is also being offered for sale as a part of a Feed Through White Glue Laminating Line (EXF #LA-011187).

Call for Price

OSAMA S2R-1600 1600 mm (63") Top & Bottom Glue SpreaderSpecifications: -- Panel thickness 0 - 100 mm (3.94"). -- Pass line height 800 mm (31.50"). -- Feed speed 18 MPM (59 FPM).Equipped with: -- 185 mm (7.28") Dia. x 64" L Grooved anti-acid rubber-covered top & bottom applicator rolls, each with Manual brush washer, Side glue wipers. -- 21-3/4"; x 72"; x 2-3/4"; D Removable stainless steel bottom pan. -- Front & rear safety fences.NOTE: This machine is also being offered for sale as a part of a Feed Through White Glue Laminating Line (EXF #LA-011187).

Complete OSAMA Feed Through White Glue Laminating Line, with MIDWEST AUTOMATION Laminate Indexing/Lay-up Table & HMT Laminator Specifications: Line was designed to use the HMT Laminator as a pinch roller with heaters for large quantity runs. The HMT Laminator was used as a stand-alone machine for small quantity runs. Max. panel size 60" x 120" (Based on current outfeed scissor lift platform size. With a 60" x 144" or larger scissor lift, 144" L panels could be run.) Consisting of the following machines as late as 2016: AREDON 48" x 96" Electric/Hydraulic Scissor Lift Platform. 2007 OSAMA SP/RSI-1600 1600 mm (63") Top & Bottom Brush Panel Cleaner, S/N 8103, Min. panel length 430 mm (16.93"), Panel thickness 0 - 100 mm (3.94"), Feed speed 22 MPM (72 FPM), with 290 mm (11.42") Dia. Top & bottom brush rolls with 0.6 mm (0.02") Dia. Black nylon bristles, Spare pair of brushes, 460 V, 60 Cy, 3 Ph., Dimensions 108" X 36" X 70" H, Weight 1,100 Lbs. 2006 OSAMA S2R-1600 1600 mm (63") Top & Bottom Glue Spreader, S/N 20944, Panel thickness 0 - 100 mm (3.94"), Pass line height 800 mm (31.50"), Feed speed 18 MPM (59 FPM), with 185 mm (7.28") Dia. x 64" L Grooved anti-acid rubber-covered top & bottom applicator rolls, each with Manual brush washer, Side glue wipers, Removeable bottom pan, Front & rear safety fences, 230 V, 60 Cy, 3 Ph., Dimensions 90" x 30" x 60" H, Weight 1,500 Lbs. MIDWEST AUTOMATION LT 500 60” x 144” Laminate Indexing/Lay-up Table. 2016 HMT ADVANTAGE PLUS 61" Laminator, S/N 5A391, with 10.5 kW Heatbank, 208 V, 60 Cy, 1 Ph., Dimensions 120" x 83" x 55" H, Weight 1,400 Lbs., NOTE: This machine is also being offered for sale separately (EXF #LA-011186). SOUTHWORTH 5,000 Lb. Capacity 60” x 120” Electric/Hydraulic Scissor Lift Platform, with Gravity roller conveyor top. CURRENCY NOTE: Negotiable Price is listed in U.S. Dollars.

OSI SM-450 Side Matcher LineSide Matcher:FEATURES -- Directly opposing heads (Side-Matcher): Enhances width tolerance and eliminates pistol grip -- Guarantee machining accuracy of +/- 0.002"; (0.05 mm) on width and on tongue/groove position -- Through feed system in both machines: work boards as short as 9"; (229 mm) out of the defecting station; can be processed directly into the Side-Matcher -- Process twisted, crooked and bowed boards -- Hydro-lock collars on all axis -- Feed wheels on independent suspension -- Very low friction -- High precision spindle -- Very short setup time Easy and quick width adjustment -- Easy opening for tool replacement -- Hydraulic unjammingSpecifications: -- Pre-Milling top and bottom with (2) 15 HP motor -- Feed speed 200 to 450 FPM -- Board width 1 1/2" to 8" -- Board thickness: 1/2" to 1 1/2" -- Board length: minimum of 9" trough feed -- Tooling: (2) X 8", RPM 6,000 -- Spindle drive: (2) X 30 HP -- Feed wheels: (2) rows of (4) wheels on top driven by (2) 3 HP motors -- Feed rolls: (3) chromed rolls on bottom driven by (3) 2 HP motor -- Axis movement: on linear bearings

RENZO BORGONOVO, BL 94-2, ...Vertical Moulding Stacker.This 2-ARM AUTO STACKER has been specially designed to facilitate the loading of mouldings, picture frame strips, and other processed lineal parts onto drying racks. It eliminates the manual handling of workpieces which can mar the finish. It also increases productivity and efficiency compared to manual stacking. The machine can work with moulding of the same length or of varying lengths at the same time. -- Workpiece Length: 3,000 mm (118") Max. & 1,800 mm (72") min. workpiece width; 20 mm min. and 150 mm (6") max. material width cap. -- Stacking Capacity: (20 - 30) Pieces per minute. -- Overall Height: 2,200 mm (87"). - Overall width: 2,300 mm (91"). - Overall Length: 3,400 (134"). - Work Height: At Infeed 860 mm(34"). - Racks has (11) arms that extend out approx. 39" with 4" in between arms. -- Automatically loads "just painted" mouldings onto air drying rack. -- Process: As moulding exits coater, it is moved by belt conveyor to (2) arms which lift the piece up-and-over the top of the Stacker Station; coming down the other side, it places the moulding onto (2) arms, and a belt conveyor transfers the piece onto the 11-tier Drying Cart. -- Lifting can be triggered by electric photoeye to determine position of off-feed arms (arms move down as each tier of the rack is filled) and place moulding on the rack (indexing back-to-front). -- One rack included; additional racks, each ...$ 900.Machine overall dimensions: 3,400 x 2,300 x 2,200' weight: 1,200 kG.

RENZO BORGONOVO - BL 94-3, ... Vertical Moulding Stacker. This 3-ARM AUTO STACKER has been specially designed to facilitate the loading of mouldings, picture frame strips, and other processed linear parts onto drying racks.It eliminates manual handling of workpieces, which can mar the finish. It also increases productivity and efficiency compared to manual stacking. The machine can work with moulding of the same length or of varying lengths at the same time.Specifications: -- Workpiece Lengths are 4,900 mm (192") Max. & 1,500 mm (58") min. workpiece length, 20 mm min. and 150 mm (6") max. material width cap. -- Stacking Capacity - (20 - 30) pieces/Min. -- Overall Height of 2,200 mm (87"); Overall Width 2,300 mm (91"); Overall Length of 4,000 (157"). -- Work Height at Infeed 860 mm ( 34"); Racks have (11) arms that extend out approx. 39" with 4" in between arms.Operation: -- Automatically loads just-painted mouldings onto air drying rack. -- Process: As moulding exits Coater, it is moved by belt conveyor to (3) arms, which lift the piece up and over the top of the Stacker Station; coming down the other side, it places the moulding onto (3) arms. A belt conveyor transfers the piece onto the 11-tier drying cart. -- Lifting can be triggered by electric photo-eye to determine the position of off-feed arms (arms move down as each tier of the rack is filled) and place moulding on the rack (indexing back-to-front).This Stacker comes with (1) rack; additional racks are available, priced at ...$ 1,950 each

RENZO BORGONOVO MVS-2500 Automatic Sanding and Buffing MachineFOR LINEAR FRAMES AND PROFILES - Sanding and buffing of frames, rods, ledges and fitting parts of veneer, solid, raw or varnished wood, etc. (processing of 3 sides for each pass). -- Advancing speed electronically variable by inverter: 10 TO 50 M/MIN. -- Total power: kW 10,5 (14 HP) -- Compressed air: Atm 6 -- Total exhaust capacity; m3/h. 2800 (25 m/sec.) -- Working height: mm. 10 min. mm. 100 max. -- Working width: mm. 20 min. mm. 200 max. -- Working length: mm. 1200 min.DISC SANDING UNITS TYPE “SCOTCH BRITE"; (N° 4) -- Power motor: 3 HP (2.2 kW) -- Rotation speed: 1400 RPM -- Disc sanding unit holder shaft diameter: mm. 30 -- Spindle-disc sanding unit connection flange diameter: mm. 76 -- Disc sanding unit diameter: mm. 200 max. -- Disc sanding unit height: mm. 100 max. -- Dust suction hood diameter: mm. 100 -- Extraction rate: m3/h. 700 (25 m/sec.)

RENZO BORGONOVO - SP 6P, ...6-Gun Spray Machine with 3/4" - 12" width cap.3-1/4" Max, part thickness and 32" min. part length. Standard specifications: -- (6) Gun mounts made from aluminum rods and HDPE mounting brackets, for connections for (6) HVLP automatic spray guns, and (1) dual diaphragm fluid pump. (Guns and Pumps are not included). -- Complete with: Teflon coated recovery cabinet for each spray station and easy rollout feature, front access door with large viewing window & gas shock support arms. -- (2) Paint circuits with (3) spray guns each (guns not included).Features: -- Machine is operated with a central control panel and gun timing is controlled by a PLC that times the spray guns in relation to the length of the work piece and feed speed. -- PLC Records the number of workpieces and total linear feet processed in session. -- The machine is set up with infeed & outfeed conveyors that operate at any speed between 2- - 100 mpm (65 - 325 FPM) and is made up of Antistatic and Antisolvent belts and intermediate steel rollers between Spray Stations. -- 300mm (11.8" Dia.), 1.5 HP exhaust fan rated at 4,000 cbm/Hr. -- This Sprayer integrates easily into any line whether as a primary unit or as an intermediate step. -- Overall length is just under 10'.The Machine is priced with no guns or supply installed, these will need to be added by the buyer or a separate quote can be requested for guns and supply pumps.Working dimensions: -- Length: Min. 800 mm / max. infinite. -- Width: Min. 15 / 300 mm. -- Height: Min. 15 mm / max. 100 mm. -- Height of worktable: 900 mm. -- Compressed air consumption - NI/min 1,500 – 2,000. Optional: InHand Networks Industrial Router Overall machine dimensions and weight Teleservice module for remote troubleshootingPrice includes the following options: Stainless Steel carriage Teleservice module for remote service.PRICE IS FOB EAST COAST PORT, INLAND FREIGHT WILL BE QUOTED.Overall size: 3,000 x 2,900 x 2,220 mm and 800 kG (I,750 Lbs).

Call for Price

RETHPAK HC-2020 FORM-FILL AND SEAL BAGGING LINEComplete Form-Fill and Seal COMPRESSION Bagging System Specifications: -- Model HC-2020 Form-Fill and Seal Compression Bagger -- Up to (7) Bags Per Minute -- Bag Size 12" x 18" x up to 32" Long -- 60" Maximum Film Width -- Optional Film Cart Included -- Cyclone and Stand -- Walking Floor Trailer with Blue Auger Conveyor -- Control Panel, MCC -- Hydraulic Tank -- Tires for Walking Floor Trailer -- Blue Piping and Stands -- Transfer Auger Conveyor and Surge Bin -- Auger From Surge Bin to Bagger -- Transfer Belt -- Stacking Unit and Outfeed Rollcase -- Roll Lifting Device -- Shrink WrapperDecommissioning and All Associated Wiring Removed by Contractor